FWD 4.3L V6 into a 4WD Cherokee

#31

I was thinking about it the night.

And because of the V engine it might be easier to use two relative small turbocharger directly at the manifolds- which would result in a very quick and even boost.

It might also ease the built and avoid heat related problems. Exhaust would be easy to run too.

But it's just my personal opinion- maybe I have seen to many Banks twinturbo's

Does you engine already have piston oil jets to cool the underside of the pistons?

Do you already have an idea how much boost you want? Keep in mind that you will need an intercooler if you go higher than 7psi of boost.

My Jeep uses a small IHI RHB 59 turbocharger.

I plan to built a compound charger with the inducer housing of a Maserati Ghibli twinturbo.

It has been done already - just have a look at this video:

YouTube - Toch's Jeep Cherokee Xj drifting donuts

And because of the V engine it might be easier to use two relative small turbocharger directly at the manifolds- which would result in a very quick and even boost.

It might also ease the built and avoid heat related problems. Exhaust would be easy to run too.

But it's just my personal opinion- maybe I have seen to many Banks twinturbo's

Does you engine already have piston oil jets to cool the underside of the pistons?

Do you already have an idea how much boost you want? Keep in mind that you will need an intercooler if you go higher than 7psi of boost.

My Jeep uses a small IHI RHB 59 turbocharger.

I plan to built a compound charger with the inducer housing of a Maserati Ghibli twinturbo.

It has been done already - just have a look at this video:

YouTube - Toch's Jeep Cherokee Xj drifting donuts

I only plan on running around 7-8 PSI boost - with maybe the occasional spike up to 10 PSI, but even if I ran higher than 7-8 PSI all the time, an intercooler isn't really required. The OM617 in my Mercedes (same engine that Benzer1 and FTE are installing in their Jeeps) runs 10-12 PSI all the time with no intercooler and it does just fine. Guys on the Mercedes boards I frequent have tried intercoolers on them and say that unless you're running above 14 PSI, the intercooler doesn't help at all. Water/meth induction is generally considered to be more beneficial - and even that only gives a marginal improvement.

Unfortunately, the 4.3L doesn't have piston cooling oil jets. I looked at trying to put some kind of system in it, but it is just too tight and would take too much co$tly machine work on the block. That is one of the reasons I plan on keeping the boost low. I'll also have to watch my pyrometer and keep the EGTs down to around 1150 F - just to leave a little margin for error...

Last edited by CheaperJeeper; 04-28-2010 at 11:21 AM.

#32

So you have the space problem too?

I just saw my turbo sitting on the side of the engine. I have totally neglected that you use a V-engine which has a much wider stance...

Think about an additional oil cooler- I use it speed independent and temperature controlled with a 100W fan and with great success to keep engine temperatures in the green zone.

That may help you to avoid overheating.

I just saw my turbo sitting on the side of the engine. I have totally neglected that you use a V-engine which has a much wider stance...

Think about an additional oil cooler- I use it speed independent and temperature controlled with a 100W fan and with great success to keep engine temperatures in the green zone.

That may help you to avoid overheating.

#33

So you have the space problem too?

I just saw my turbo sitting on the side of the engine. I have totally neglected that you use a V-engine which has a much wider stance...

Think about an additional oil cooler- I use it speed independent and temperature controlled with a 100W fan and with great success to keep engine temperatures in the green zone.

That may help you to avoid overheating.

I just saw my turbo sitting on the side of the engine. I have totally neglected that you use a V-engine which has a much wider stance...

Think about an additional oil cooler- I use it speed independent and temperature controlled with a 100W fan and with great success to keep engine temperatures in the green zone.

That may help you to avoid overheating.

I'll use the tranny cooler that is already built into the radiator for cooling the transmission.

FWIW, this engine is also pretty heat sensitive. It has aluminum heads and overheating can warp them pretty easily. I have come up with a fail-safe to prevent that happening. The injection pump has an electric solenoid that cuts off the fuel to shut the engine off. I'm going to put a "snap button" type temp switch inline with the fuel cutoff soleniod to interrupt power to it whenever the temp gets over about 240 degrees F. After doing all this work I don't want to take a chance of having the engine overheat and ruin the heads. I will probably install an oil pressure switch inline too so that if the engine looses oil pressure it will shut it off too...

Last edited by CheaperJeeper; 04-28-2010 at 02:30 PM.

#34

It will already be to late when the shut off comes! Ask me...

I added an additional aux coolant pump which itensifies coolant flow through the heater to get rid od added heat,maybe this is possible at your engine two.

Also when you shut off your engine heat in the heads will raise enormous. Just check it out after you used the Jeep. After 10 minutes the heat will be in the red area.

To prevent this I built an aftercooling system with this above mentioned coolant pump and a timer control unit to circulate the coolant. It also switches the A/C radiator fan on. The Jeep has the Visco fan too.

I use the stock water /oil cooler and an additional oil cooler with fan because the stock unit is still not enough.

240°F thats pretty high! almost boiling temperature of the coolant?

Isn't there a possibility to decrease engine speed without shut off- maybe also adding a secondary cooling system?

We use that in our weapon system as an aux cooling unit during extreme weather conditions.

I mounted my oil cooler into the bumper( the reason for the fan use) to avoid obstruction in front of the radiator.

The oil cooler fan has a thermo switch which engages at 212°F, maybe this seems to be a bit low, but the egine internal temperature is much higher under load.

The oil raises pretty quick under heavy load. And with a trailer or a step incline the oil temperaure jumps up to 248°- 260°F. The oil cooler takes care about this real quick and decreases it within 5 minutes.

I added an additional aux coolant pump which itensifies coolant flow through the heater to get rid od added heat,maybe this is possible at your engine two.

Also when you shut off your engine heat in the heads will raise enormous. Just check it out after you used the Jeep. After 10 minutes the heat will be in the red area.

To prevent this I built an aftercooling system with this above mentioned coolant pump and a timer control unit to circulate the coolant. It also switches the A/C radiator fan on. The Jeep has the Visco fan too.

I use the stock water /oil cooler and an additional oil cooler with fan because the stock unit is still not enough.

240°F thats pretty high! almost boiling temperature of the coolant?

Isn't there a possibility to decrease engine speed without shut off- maybe also adding a secondary cooling system?

We use that in our weapon system as an aux cooling unit during extreme weather conditions.

I mounted my oil cooler into the bumper( the reason for the fan use) to avoid obstruction in front of the radiator.

The oil cooler fan has a thermo switch which engages at 212°F, maybe this seems to be a bit low, but the egine internal temperature is much higher under load.

The oil raises pretty quick under heavy load. And with a trailer or a step incline the oil temperaure jumps up to 248°- 260°F. The oil cooler takes care about this real quick and decreases it within 5 minutes.

#35

Not if I mount the snap-button right on side of the aluminum head. I said 240*F but that was just an example. I actually plan on using a non-contact thermometer to figure out what the "normal" operating temps are and then I'll get a "snap-button switch" that opens at a temp 20-30 degrees higher than that.

That doesn't sound normal to me. Neither my F250 with a 6.9 IDI and a Banks turbo or my Mercedes 300CD with the OM617 turbo do that. The temps might go up a few degrees after shutdown, but nothing like what you're describing...

The oil cooler I was talking about that I plan on using came off a 6 cylinder cummins in a bread truck. I think it ought to be enough for this little 4.3L

Like I said, 240* was just an example and I'll figure out the actual temperature to set my cutoff once I have it running a little while. I'll keep that secondary cooling idea in mind and if I have a problem I can do something like that

Yeah, I'll put a thermo switch on mine too - probably something in the 220* range...

I added an additional aux coolant pump which itensifies coolant flow through the heater to get rid od added heat,maybe this is possible at your engine two.

Also when you shut off your engine heat in the heads will raise enormous. Just check it out after you used the Jeep. After 10 minutes the heat will be in the red area.

Also when you shut off your engine heat in the heads will raise enormous. Just check it out after you used the Jeep. After 10 minutes the heat will be in the red area.

240°F thats pretty high! almost boiling temperature of the coolant?

Isn't there a possibility to decrease engine speed without shut off- maybe also adding a secondary cooling system?

We use that in our weapon system as an aux cooling unit during extreme weather conditions.

Isn't there a possibility to decrease engine speed without shut off- maybe also adding a secondary cooling system?

We use that in our weapon system as an aux cooling unit during extreme weather conditions.

I mounted my oil cooler into the bumper( the reason for the fan use) to avoid obstruction in front of the radiator.

The oil cooler fan has a thermo switch which engages at 212°F, maybe this seems to be a bit low, but the egine internal temperature is much higher under load.

The oil raises pretty quick under heavy load. And with a trailer or a step incline the oil temperaure jumps up to 248°- 260°F. The oil cooler takes care about this real quick and decreases it within 5 minutes.

The oil cooler fan has a thermo switch which engages at 212°F, maybe this seems to be a bit low, but the egine internal temperature is much higher under load.

The oil raises pretty quick under heavy load. And with a trailer or a step incline the oil temperaure jumps up to 248°- 260°F. The oil cooler takes care about this real quick and decreases it within 5 minutes.

#36

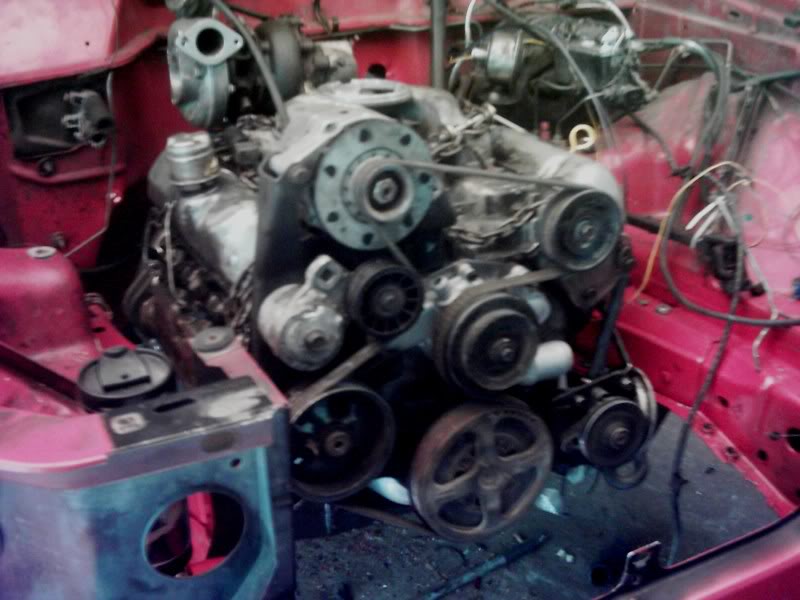

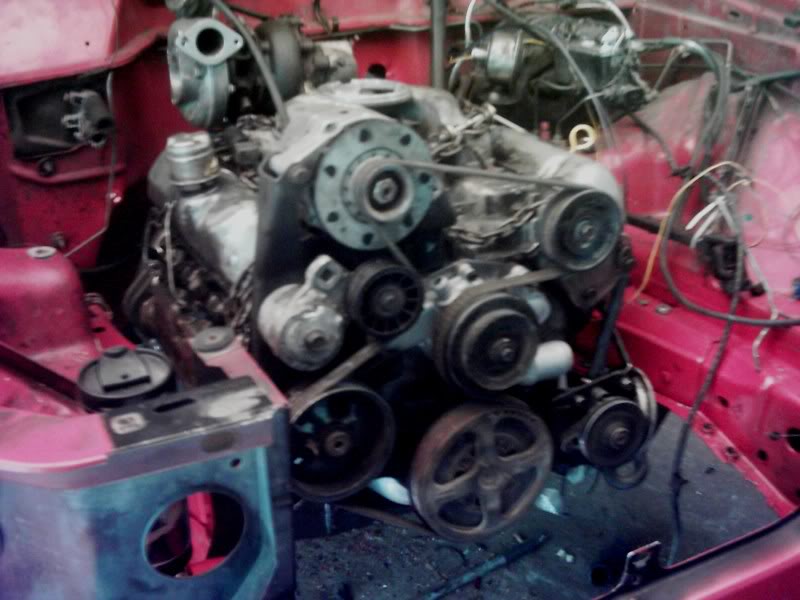

Made some more progress the last couple of weeks. Its going a little slower than I'd like, but I'm making progress none the less...

I discovered that the blowby filter and CDR mounted on the front corner of the passenger side valve cover stuck up about an inch too high, so I swapped valve covers to move it from the passenger front corner to the drivers rear corner of the engine bay. Sounds simple, but taking the valve covers off required removing all the fuel injector lines. The relocation also required reversing the inlet on the intake bridge to make them point to the rear instead of the front.

Fabricated the idler pulley bracket to take the place of the AC compressor

Finished up the final fitment of the turbo...

...and the routing of the pipes

I discovered that the blowby filter and CDR mounted on the front corner of the passenger side valve cover stuck up about an inch too high, so I swapped valve covers to move it from the passenger front corner to the drivers rear corner of the engine bay. Sounds simple, but taking the valve covers off required removing all the fuel injector lines. The relocation also required reversing the inlet on the intake bridge to make them point to the rear instead of the front.

Fabricated the idler pulley bracket to take the place of the AC compressor

Finished up the final fitment of the turbo...

...and the routing of the pipes

Last edited by CheaperJeeper; 05-11-2010 at 11:37 PM.

#37

...then set it back into the engine bay to see how everything fits.

Clearance is a little tight on both sides...

...which is why the custom manifolds were necessary. Once I was sure that everything fits, I pulled the engine back out and removed the turbo and turbo pipes. So now I'm ready to put the NA pipes back on, and put the final touches on the cooling system, and oil blowby piping in place and its ready to go back into the engine bay for the final time.

Clearance is a little tight on both sides...

...which is why the custom manifolds were necessary. Once I was sure that everything fits, I pulled the engine back out and removed the turbo and turbo pipes. So now I'm ready to put the NA pipes back on, and put the final touches on the cooling system, and oil blowby piping in place and its ready to go back into the engine bay for the final time.

Last edited by CheaperJeeper; 05-12-2010 at 09:39 AM.

#40

Yup, sure did. The AC compressor was mounted on top right next to the alternator. I lowered the alternator about an inch (modified the brackets) and removed the AC compressor to get it all low enough to clear the hood. When it came time to figure out where to put the idler to replace the AC pulley, I discovered that the belt was too short. Fortunately I had a belt off a 4.0 Cherokee handy and it was just the right length.

Thanks! It might almost look factory IF it weren't for my crappy looking welds!

OH WELL, they may not look the greatest, but so far I have NEVER had one of my welds fail under stress, and I guess strength is more important than looks...

OH WELL, they may not look the greatest, but so far I have NEVER had one of my welds fail under stress, and I guess strength is more important than looks...