1976 Ford Courier v2203/t5 swap

#51

The 1752 is ok but not as good as the K03. It did not build the high boost on my IDI engine, haven't tried it on my DI but I do not believe it would be any different. I think it's a little bit too big for the engine. The K03 is a fantastic fit!

#52

#53

I will admit that I know pretty close to nothing about turbos. Especially sizing them. I know by everyone else experiences here. I want to understand what all the numbers mean.

can someone point me to a good site explaining the basics and not so basic info on turbos?

I won a gt1752 on eBay. I will install as is. But wondering if there is something else I can do to get it to spool earlier. Hybrid?

thanks

ken

can someone point me to a good site explaining the basics and not so basic info on turbos?

I won a gt1752 on eBay. I will install as is. But wondering if there is something else I can do to get it to spool earlier. Hybrid?

thanks

ken

#54

I'm not very familiar with Garretts to know what can be done, but if you're looking at changing housings and wheels, you may end up spending more than getting a different turbo.

Trying to help, I apologize if this is too simple, but I've had success improving spool in 3 basic areas.

-Velocity

-Heat retention

-Flow

Velocity

Basically, you want the exhaust to reach the turbo as quickly as possible, with minimal restrictions. Larger isn't always better in this case. You don't want it so small that it builds excessive drive pressure, but our engines are pretty small anyway. Just look at the relative size of the uppipes on Duramax and Powerstrokes.

Heat retention

Simple energy principal. You want the heat energy going through the turbine, not being lost heating the engine compartment. I noticed a dramatic difference when I went to the ceramic coated turbo manifold. Unfortunately it's impossible to know whether the manifold or the ceramic coating made the biggest difference.

Flow

This is the most common. Once the exhaust has done its work, then it needs to GTF out of the way through the highest flowing, least restrictive post turbine exhaust you can fit. Obviously it only helps up to a point, so going 6" over 3" on a 2.2 isn't really going to help much, but despite claims from others that 2.25" exhaust is way more than our engines need, going to 3" on my resulted in a big performance gain, and drop in EGTs. Also strangely, it's quieter than the 2.25"...

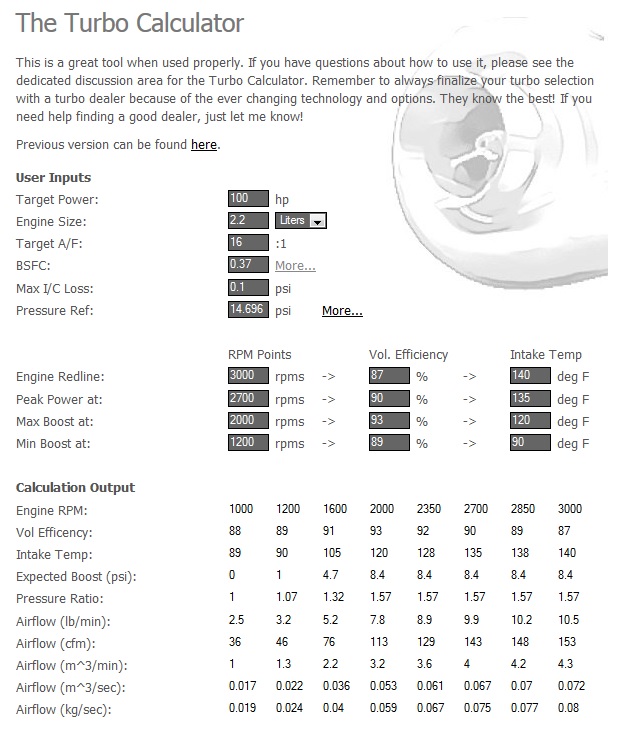

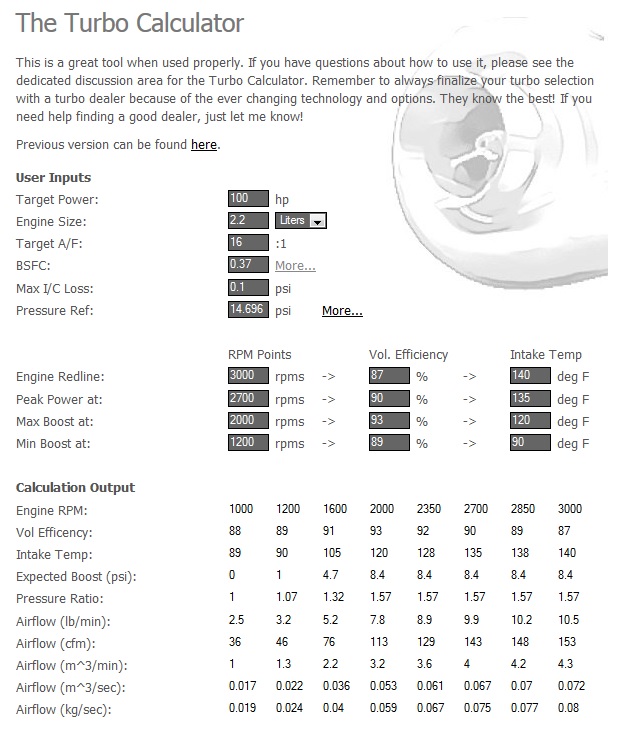

I use the Squirrel Performance turbo calculator when I'm trying to figure out how a turbo will interact with our engines. It's obviously not the most precise thing, but it helps give a good general idea.

Squirrel Performance

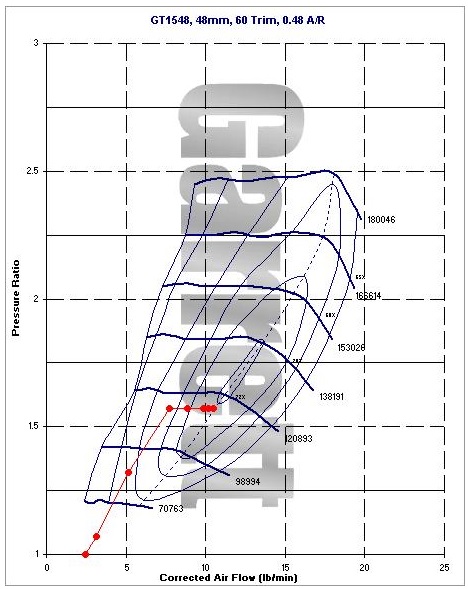

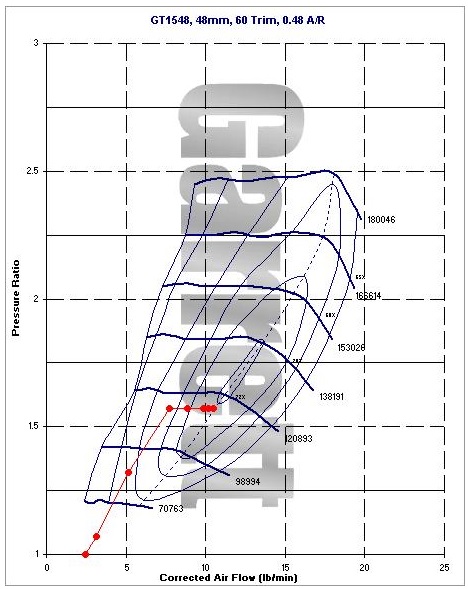

Here's a quick entry off the top of my head. They list a lot of K03 maps, and I'm not sure which one people are using. They also don't have a 1752 map listed, so I used the 1548 map just to show how it plots.

And here's a 1752 map that I pulled off of a quick google search.

Trying to help, I apologize if this is too simple, but I've had success improving spool in 3 basic areas.

-Velocity

-Heat retention

-Flow

Velocity

Basically, you want the exhaust to reach the turbo as quickly as possible, with minimal restrictions. Larger isn't always better in this case. You don't want it so small that it builds excessive drive pressure, but our engines are pretty small anyway. Just look at the relative size of the uppipes on Duramax and Powerstrokes.

Heat retention

Simple energy principal. You want the heat energy going through the turbine, not being lost heating the engine compartment. I noticed a dramatic difference when I went to the ceramic coated turbo manifold. Unfortunately it's impossible to know whether the manifold or the ceramic coating made the biggest difference.

Flow

This is the most common. Once the exhaust has done its work, then it needs to GTF out of the way through the highest flowing, least restrictive post turbine exhaust you can fit. Obviously it only helps up to a point, so going 6" over 3" on a 2.2 isn't really going to help much, but despite claims from others that 2.25" exhaust is way more than our engines need, going to 3" on my resulted in a big performance gain, and drop in EGTs. Also strangely, it's quieter than the 2.25"...

I use the Squirrel Performance turbo calculator when I'm trying to figure out how a turbo will interact with our engines. It's obviously not the most precise thing, but it helps give a good general idea.

Squirrel Performance

Here's a quick entry off the top of my head. They list a lot of K03 maps, and I'm not sure which one people are using. They also don't have a 1752 map listed, so I used the 1548 map just to show how it plots.

And here's a 1752 map that I pulled off of a quick google search.

#55

Thank you RED.

ok.. here is what I am working with

Velocity- just finished my new manifold flange this morning. Will be running 1.25 OD 16 gauge tubing which will put me at 1.12" ID the ports on the kubota measure 1.10" .

All tubing is manderel bent and the bends are on a 3.75 radius I can go tighter but like the sweeping radius. We will see if I can pull it off with this radius.

Trying to keep the velocity up. I will be making my own merge collector with 4 x 1.25" into a T25 exhaust flange. Going to try to keep exhaust lengths as equal as I can.

Heat Retention- When done I will wrap the header with exhaust wrap for initial testing and once I replace the motor with a DI I will probably get it coated. this is where the thicker wall would have been nice but going to experiment with this for now.

Flow - DP will most likely be 2.5 inch with a flex pipe. 3 inch would be nice but my truck is a 2wd and running only 215/70/14. Plus I plan to lower it a little more if i can.

Now with all this I am hoping this turbo will work out okay. I am not dead set on this turbo but since i have it i want to try it.

the turbo may be a little big but the truck is light and gearing should help get out of any lag.also looking to low center mount the turbo. should make for a clean install but i will have to get drafty with the motor mounts.

Not turbo related

Drivetrain- my truck right now has a 1.8l mazda with a 4 sp. Gearing is pretty high numerically along with the small tire size. it is very revvy. Not a good combo for a diesel but I may have a way around that.

I really dont want to replace the rear end or regear.

Found out recently a friend parted out a 94 lt1 camaro and has a nice little t56 sitting on his shop floor. Hoping to trade my running 396 chevy big block, a running good 4.3l chevy and do some machine work for said t56 along with all clutch flywheel slave and driveshaft..

once this all comes together i am going to tackle figuring out intercooler and piping. waiting for turbo to arrive.

my first exhaust flange, messed up with a little programming on the first exhaust port but for mock up it fit great.

Hopefully later today I will knock out the t25 flange

Thanks

Ken

ok.. here is what I am working with

Velocity- just finished my new manifold flange this morning. Will be running 1.25 OD 16 gauge tubing which will put me at 1.12" ID the ports on the kubota measure 1.10" .

All tubing is manderel bent and the bends are on a 3.75 radius I can go tighter but like the sweeping radius. We will see if I can pull it off with this radius.

Trying to keep the velocity up. I will be making my own merge collector with 4 x 1.25" into a T25 exhaust flange. Going to try to keep exhaust lengths as equal as I can.

Heat Retention- When done I will wrap the header with exhaust wrap for initial testing and once I replace the motor with a DI I will probably get it coated. this is where the thicker wall would have been nice but going to experiment with this for now.

Flow - DP will most likely be 2.5 inch with a flex pipe. 3 inch would be nice but my truck is a 2wd and running only 215/70/14. Plus I plan to lower it a little more if i can.

Now with all this I am hoping this turbo will work out okay. I am not dead set on this turbo but since i have it i want to try it.

the turbo may be a little big but the truck is light and gearing should help get out of any lag.also looking to low center mount the turbo. should make for a clean install but i will have to get drafty with the motor mounts.

Not turbo related

Drivetrain- my truck right now has a 1.8l mazda with a 4 sp. Gearing is pretty high numerically along with the small tire size. it is very revvy. Not a good combo for a diesel but I may have a way around that.

I really dont want to replace the rear end or regear.

Found out recently a friend parted out a 94 lt1 camaro and has a nice little t56 sitting on his shop floor. Hoping to trade my running 396 chevy big block, a running good 4.3l chevy and do some machine work for said t56 along with all clutch flywheel slave and driveshaft..

once this all comes together i am going to tackle figuring out intercooler and piping. waiting for turbo to arrive.

my first exhaust flange, messed up with a little programming on the first exhaust port but for mock up it fit great.

Hopefully later today I will knock out the t25 flange

Thanks

Ken

#56

Velocity- just finished my new manifold flange this morning. Will be running 1.25 OD 16 gauge tubing which will put me at 1.12" ID the ports on the kubota measure 1.10" .

All tubing is manderel bent and the bends are on a 3.75 radius I can go tighter but like the sweeping radius. We will see if I can pull it off with this radius.

Trying to keep the velocity up. I will be making my own merge collector with 4 x 1.25" into a T25 exhaust flange. Going to try to keep exhaust lengths as equal as I can.

Heat Retention- When done I will wrap the header with exhaust wrap for initial testing and once I replace the motor with a DI I will probably get it coated. this is where the thicker wall would have been nice but going to experiment with this for now.

All tubing is manderel bent and the bends are on a 3.75 radius I can go tighter but like the sweeping radius. We will see if I can pull it off with this radius.

Trying to keep the velocity up. I will be making my own merge collector with 4 x 1.25" into a T25 exhaust flange. Going to try to keep exhaust lengths as equal as I can.

Heat Retention- When done I will wrap the header with exhaust wrap for initial testing and once I replace the motor with a DI I will probably get it coated. this is where the thicker wall would have been nice but going to experiment with this for now.

Flow - DP will most likely be 2.5 inch with a flex pipe. 3 inch would be nice but my truck is a 2wd and running only 215/70/14. Plus I plan to lower it a little more if i can.

Now with all this I am hoping this turbo will work out okay. I am not dead set on this turbo but since i have it i want to try it.

the turbo may be a little big but the truck is light and gearing should help get out of any lag.also looking to low center mount the turbo. should make for a clean install but i will have to get drafty with the motor mounts.

The original turbo that I used off of a WRX was huge compared to these, and it didn't work THAT horribly. It just liked to be over 2200RPM to really do anything more than 6PSI. I still wish my turbo did better under 2000RPM, but I'm dealing with around 12PSI at that RPM and peaking in the 20's. More PSI lower may not be a reasonable expectation with this engine.

My biggest issue with the Jeep has always been wind load, it's just working it's *** off at anything over 45mph. I once found a guy that had swapped a GM6.2 diesel out of a working 2wd truck that had been getting 24mpg into a Wrangler. The mpg for the engine dropped to 16 in the Wrangler...

Found out recently a friend parted out a 94 lt1 camaro and has a nice little t56 sitting on his shop floor. Hoping to trade my running 396 chevy big block, a running good 4.3l chevy and do some machine work for said t56 along with all clutch flywheel slave and driveshaft..

#58

#59

#60

Hi Red, and Ken, I don't want to thread jack too much, Red I played with the squirrel calculator and I like it a lot, better than the other calculators I have used. I I did see where you got the bsfc from for the squirrel site, but this is what I saw from a Kubota spec page. The BSFC seems to have a impact on the pressure ratio which in turn will point to different turbos.

So do we use the generic .37 or .38 listed for turbocharged diesels, on squirrel or the.399 listed for the normal aspirated Kubota. also bsfc listed from this same site for the OE turbo kubotas is still higher than the squirrel site's .38 or .37

I can't seem to copy the spec sheet so here is a link

DieselEngineMotor.Com - Kubota Diesel Engine V2203

So do we use the generic .37 or .38 listed for turbocharged diesels, on squirrel or the.399 listed for the normal aspirated Kubota. also bsfc listed from this same site for the OE turbo kubotas is still higher than the squirrel site's .38 or .37

I can't seem to copy the spec sheet so here is a link

DieselEngineMotor.Com - Kubota Diesel Engine V2203