Questions

#1

I have a 96 12 valve that i just started playing with. I've owned a lot of Cummins, but never tuned on any of them. Reading the threads on here has caused me to have a lot of probably stupid questions, but here I go anyway. I am assuming that delivery valves and injectors are two different things?? Also fuel plates; can I gain hp by making the slot longer in the stock plate, what happens when you take the plate out? Is there an easy way to get more boost out of the turbo? Thanks in adavnced for nay help.

#2

I am assuming that delivery valves and injectors are two different things??

Also fuel plates; can I gain hp by making the slot longer in the stock plate

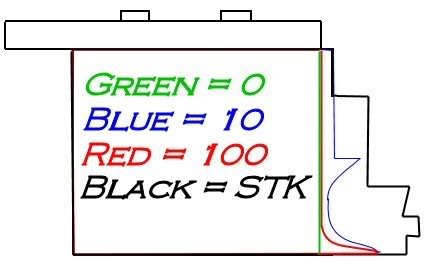

Heres a pic.

what happens when you take the plate out?

Is there an easy way to get more boost out of the turbo?

A little more info here; CumminsDatabase.com :: Turning Up A P7100 Pump

It is VERY important to install gauges, at least EGT, before modifying fuel on a diesel. They can easily get hot enough to damage the aluminum parts.

#4

here is the article by Dieselminded.........he wrote the one for CF to but they say arther is unknown

The steps for turning up a P7100 pump are:

1) Remove your AFC Housing

2) Mod Your Fuel Plate either slide it forward or purchase a cut one

3) Adjust the governor lever to contact the fuel plate

4) Crank the star Wheel Towards the motor

5) Slide The AFC housing all the way forward

Details Below......

First of all Know Your Pump

First of all Know Your Pump

Only 1994-1998 trucks have the P7100 Pump

The Control Parts List number or CPL number is located on the engine data plate, which can be found on the drivers side of the timing gear cover. The engine data plate includes such information as the CPL number, engine serial number, and pump timing information.

160hp

180hp

215hp

If you do almost any pump work you have to take the AFC housing off.

If you do almost any pump work you have to take the AFC housing off.

Remove front passenger side AFC housing break off screw. NOTE: This screw is a factory break off screw with rounded head and no screw driver, allen head or TORX slot. Use a hand impact tool with a 6 inch long 1/4" extension and a T15 TORX bit to remove this screw. A center punch may be required to start a hole in the center of this screw. Set the hand impact tool in the removal position (counter clockwise) and use light hammer taps on the impact tool to loosen this screw. Tap progressively harder on the impact tool until the screw loosens. This method of removal forms a TORX shape into the screw allowing it to be reinstalled later with the T15 TORX bit. In some cases the hole in the top of this screw is too large for the T15 bit thus use the T20 TORX bit. There is usually a lock washer and flat washer under each of these screws. OPTIONAL: A sharp chisel can be used to remove the break off screw by making a notch in the outside diameter of the head, then applying a tangential force with light blows to the chisel counterclockwise to remove the screw.

AFC Cut Away

AFC Cut Away

Fuel Plate

Fuel Plate

With the AFC housing removed you can now see the fuel plate .

With the AFC housing removed you can now see the fuel plate .

Sliding the stock plate will increase HP quite a bit. However, the stock plate profile is not designed for that so the result is usually EGT problems. Home ground plates are not a good idea either. Pump experts say to NEVER remove the plate completely. There is a pin in the pump that will eventually wear and break causeing very expensive damage. Slide the plate ATW Foward and if you still want more contact TST for a Cut Plate , they will recommend one for your truck

This is what it looks like under the fuel plate

This is what it looks like under the fuel plate

Governor Lever Adjustment

This is a cut away view of the governor of a P7100 pump. Notice how the lever hit the cam plate flush at the very bottom edge. To check your adjustment the throttle lever needs to be moved until the lever just touches the cam plate. With the AFC housing removed, look down through the opening behind the cam plate and see where the lever is striking the plate. This should be done with the Fuel Shutoff Solenoid in the run ( or pulled up ) position.

This is a cut away view of the governor of a P7100 pump. Notice how the lever hit the cam plate flush at the very bottom edge. To check your adjustment the throttle lever needs to be moved until the lever just touches the cam plate. With the AFC housing removed, look down through the opening behind the cam plate and see where the lever is striking the plate. This should be done with the Fuel Shutoff Solenoid in the run ( or pulled up ) position.

Where the lever strikes the cam plate will vary depending on the style and design of the cam plate you are using. For plates similar to the stock plate, like shown below, this lever is set correctly. It is adjusted so the lever is flush with the bottom edge of the plate, and does not ride under the plate.

(Picture Courtesy of BD Power)

For cam plates, like a TST #6 for example, that have a taper at the very bottom of the plate, adjust the lever so the lever hits at the tip of the bottom nose on the plate. It is OK to be slightly below that. However too far down causes the lever to be held back as the RPM's rise. This causes the loss in bottom end power, with the sudden surge as the lever finally clears the nose and hits the main fueling curve.

For cam plates, like a TST #6 for example, that have a taper at the very bottom of the plate, adjust the lever so the lever hits at the tip of the bottom nose on the plate. It is OK to be slightly below that. However too far down causes the lever to be held back as the RPM's rise. This causes the loss in bottom end power, with the sudden surge as the lever finally clears the nose and hits the main fueling curve.

The steps for turning up a P7100 pump are:

1) Remove your AFC Housing

2) Mod Your Fuel Plate either slide it forward or purchase a cut one

3) Adjust the governor lever to contact the fuel plate

4) Crank the star Wheel Towards the motor

5) Slide The AFC housing all the way forward

Details Below......

First of all Know Your Pump

First of all Know Your PumpOnly 1994-1998 trucks have the P7100 Pump

The Control Parts List number or CPL number is located on the engine data plate, which can be found on the drivers side of the timing gear cover. The engine data plate includes such information as the CPL number, engine serial number, and pump timing information.

Engine Model

160hp

180hp

215hp

(California)

195 HP

195 HP

CPL

Numbers

Numbers

1549, 1550

1551, 1552

1553, 1815

1816, 1959

1839, 1968

1551, 1552

1553, 1815

1816, 1959

1839, 1968

2022

2174

2174

2023

2175

2175

1863

AFC Removal If you do almost any pump work you have to take the AFC housing off.

If you do almost any pump work you have to take the AFC housing off. Remove front passenger side AFC housing break off screw. NOTE: This screw is a factory break off screw with rounded head and no screw driver, allen head or TORX slot. Use a hand impact tool with a 6 inch long 1/4" extension and a T15 TORX bit to remove this screw. A center punch may be required to start a hole in the center of this screw. Set the hand impact tool in the removal position (counter clockwise) and use light hammer taps on the impact tool to loosen this screw. Tap progressively harder on the impact tool until the screw loosens. This method of removal forms a TORX shape into the screw allowing it to be reinstalled later with the T15 TORX bit. In some cases the hole in the top of this screw is too large for the T15 bit thus use the T20 TORX bit. There is usually a lock washer and flat washer under each of these screws. OPTIONAL: A sharp chisel can be used to remove the break off screw by making a notch in the outside diameter of the head, then applying a tangential force with light blows to the chisel counterclockwise to remove the screw.

AFC Cut Away

AFC Cut Away Fuel Plate

Fuel Plate With the AFC housing removed you can now see the fuel plate .

With the AFC housing removed you can now see the fuel plate . Sliding the stock plate will increase HP quite a bit. However, the stock plate profile is not designed for that so the result is usually EGT problems. Home ground plates are not a good idea either. Pump experts say to NEVER remove the plate completely. There is a pin in the pump that will eventually wear and break causeing very expensive damage. Slide the plate ATW Foward and if you still want more contact TST for a Cut Plate , they will recommend one for your truck

Governor Lever Adjustment

This is a cut away view of the governor of a P7100 pump. Notice how the lever hit the cam plate flush at the very bottom edge. To check your adjustment the throttle lever needs to be moved until the lever just touches the cam plate. With the AFC housing removed, look down through the opening behind the cam plate and see where the lever is striking the plate. This should be done with the Fuel Shutoff Solenoid in the run ( or pulled up ) position.

This is a cut away view of the governor of a P7100 pump. Notice how the lever hit the cam plate flush at the very bottom edge. To check your adjustment the throttle lever needs to be moved until the lever just touches the cam plate. With the AFC housing removed, look down through the opening behind the cam plate and see where the lever is striking the plate. This should be done with the Fuel Shutoff Solenoid in the run ( or pulled up ) position.Where the lever strikes the cam plate will vary depending on the style and design of the cam plate you are using. For plates similar to the stock plate, like shown below, this lever is set correctly. It is adjusted so the lever is flush with the bottom edge of the plate, and does not ride under the plate.

(Picture Courtesy of BD Power)

For cam plates, like a TST #6 for example, that have a taper at the very bottom of the plate, adjust the lever so the lever hits at the tip of the bottom nose on the plate. It is OK to be slightly below that. However too far down causes the lever to be held back as the RPM's rise. This causes the loss in bottom end power, with the sudden surge as the lever finally clears the nose and hits the main fueling curve.

For cam plates, like a TST #6 for example, that have a taper at the very bottom of the plate, adjust the lever so the lever hits at the tip of the bottom nose on the plate. It is OK to be slightly below that. However too far down causes the lever to be held back as the RPM's rise. This causes the loss in bottom end power, with the sudden surge as the lever finally clears the nose and hits the main fueling curve.

Thread

Thread Starter

Forum

Replies

Last Post

Diesel Bombers

General Diesel Related

0

11-28-2014 09:50 PM

Diesel Bombers

General Diesel Related

0

11-12-2014 08:10 AM