Dual Lift Pump Install

#1

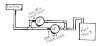

Dual Lift Pump Plumbing

Iíll start by explaining the system pictured here and some of the reasons as to why it is built the way it is just in case it gives somebody else any bright ideas. Iíll follow that with just a basic diagram of the requirements to any system you want to build.

In my case I built this one to cover all the bases. Both pumps are mounted on an aluminum base. In the event that I needed to work on them I would remove two bolts holding this base to the frame rail and a fitting on each end of it and I could pull the whole assembly out and work on a bench instead of on my back with fuel dripping down my arms.

I installed a pressure gauge on one of the pumps so that if I had both pumps running and lost some pressure I would be able to look at the gauge and know which pump was dead at a glance. I later added a switch so that I could control the on and off for each pump independently and that did away with the need for the gauge but it was there so I left it.

I also use a small piece of rubber mat behind the pumps. Itís probably not needed and never called for in any instructions I have ever seen but in my mind I think it helps absorb some of the road shock and vibration that canít be good for electrical motors. You can buy isolators for this but they are expensive and not very durable.

Most important of all here. Every LP I have ever seen has an in internal bypass built into it to control fuel pressure. The two round red barrels you see in the lines are one way check valves. They prevent the stronger pump from feeding fuel backwards through the weaker pump. You have to have one of these on the outgoing fuel side of each pump.

Now if youíre designing your own system the diagram shown here shows all the requirements. Past this you can do anything you want to personalize it. (Excuse the artwork, it's not a strongpoint)

You have to have the following:

1. A T-fitting splitting the lines someplace before the first Lift Pump.

2. A T-fitting bringing the lines back together someplace between the second lift pump and the filter.

3. A one way check valve on the outgoing fuel line of each pump.

Recommendations:

1. Either a switch to turn each pump on and off independently or use a Hobbs Pressure switch on the second pump so that it will turn on automatically if your fuel pressure drops below a pre-set psi.

2. Get rid of all the Banjo bolts and replace them with High Pressure Fuel Fittings. They only cost a few dollars each and the Banjoís are probably the single most restrictive points in your fuel system.

#3

Question: is this a fail safe or is it intended to work in parallel? If so,m what is the pressure at the VP and if you are going to all this trouble why not add additional filtration to the lines?

Good job.

Good job.

#4

There is filters on the inlet of both pumps. I believe only 1 pump works at a time - if one fails, he switches to the other pump.

#6

My personal preferance for pressure regulation is an inline return regulator. Hilborn Bypass

With the PE Pumps I had installed in the picture I just set the internal pressure to 18psi and didn't need the additional regulator. But some pumps can be set and some are built in.

#8

Those two were junk pumps from the beginning that I did a home rebuild job on and then installed them to experiment with. I ran them for well into a year. I killed the first one out because I didn't have a switch installed when I put them in so both pumps ran continuously. It wore out the internal bypass on one of them. There were several lessons learned on this, that's why I thought I'd save the next guy makin the same mistakes.

I will say that the dual pump system does work great as long as you use the components listed. It really is a no fail setup. Even if one pump completely dies you always have another runnin that is not interfering with the good pump and when you need extra fuel pressure it's right there.

This new belt drive sytem I have now is even intended to be used as a dual pump. It is supposed to have an electric pump that kicks in for a few seconds during startup to prime the lines. Since it runs off the engine flywheel it doesn't move fuel until the engine is turning. Right now I don't have the extra pump on it though and have never had a problem with the truck not starting. I have full pressure by the time the truck get's done even turning over and starting, so within the first second it's up to 18psi.

I will say that the dual pump system does work great as long as you use the components listed. It really is a no fail setup. Even if one pump completely dies you always have another runnin that is not interfering with the good pump and when you need extra fuel pressure it's right there.

This new belt drive sytem I have now is even intended to be used as a dual pump. It is supposed to have an electric pump that kicks in for a few seconds during startup to prime the lines. Since it runs off the engine flywheel it doesn't move fuel until the engine is turning. Right now I don't have the extra pump on it though and have never had a problem with the truck not starting. I have full pressure by the time the truck get's done even turning over and starting, so within the first second it's up to 18psi.

#9

Just to be sure I was clear on this. You can use any pumps you want to use and add anything in the way of filters or anything else you want to add here. This was intended to be a guide to the basic things needed to all dual pump systems.

good stuff to have here.

good stuff to have here.