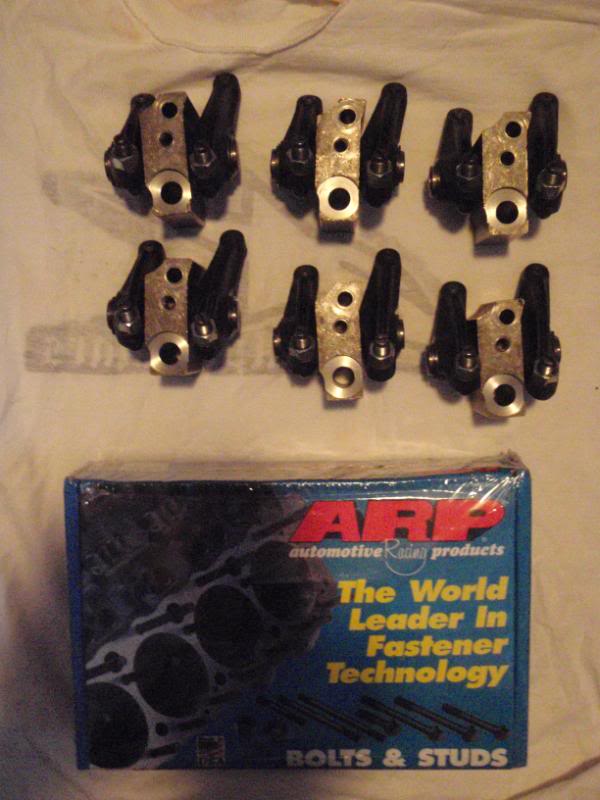

head stud????

#11

#12

Okay I installed the head studs on the truck last night and everything seemed to have worked very well.....and yes i left the washer off the rocker pedestals...there is no reason for that washer on the pedestal exept for friction but the pedestal is hard enough itself to support the nut....gonna do a once over tonight and put everything else back to gether ....thanks everyone

#13

and yes i left the washer off the rocker pedestals...there is no reason for that washer on the pedestal exept for friction but the pedestal is hard enough itself to support the nut....

The washers are made of a much harder material than the rocker pedestals, and will create less drag on the nut when you torque it down. So to get the most accurate torque readings, you need the washers(this isn't as citical with the 90/90 method). Also, if you use the washers on some studs and not others, you won't have consistant torque across the head. This is most critical on the long studs, where you left out the washers. If you're going to spend the time and money to do studs, take full advantage of them and do them right!

#14

The washers are made of a much harder material than the rocker pedestals, and will create less drag on the nut when you torque it down. So to get the most accurate torque readings, you need the washers(this isn't as citical with the 90/90 method). Also, if you use the washers on some studs and not others, you won't have consistant torque across the head. This is most critical on the long studs, where you left out the washers. If you're going to spend the time and money to do studs, take full advantage of them and do them right!

#16

I would do the mill. I would not want to take a short cut over $50. That is just me. You spent alot of money on they and not taking full advantage of the money. I know if it was only 50 instead of 200 then maybe..on a waterpump but not on a head. also with that much pressure you might warp the head.....who knows...not worth the 50 impo though...

good luck

good luck

#17

Why even ask our opinions if you'll just do it the easiest way anyway? When I work on a truck I always tell the person what needs to be done to hold what they want and the firts thing they ask is how much will that cost, welp it'll cost a whole lot more when it flys apart and takes everything around it out at the same time.

Good luck with your decision.

Good luck with your decision.

#18

Why even ask our opinions if you'll just do it the easiest way anyway? When I work on a truck I always tell the person what needs to be done to hold what they want and the firts thing they ask is how much will that cost, welp it'll cost a whole lot more when it flys apart and takes everything around it out at the same time.

Good luck with your decision.

Good luck with your decision.

#19

Thread

Thread Starter

Forum

Replies

Last Post

TheMacster

5.9L 24V Performance

2

04-14-2015 07:01 PM