Team Manne Van Janne Truck Puller team from the Netherlands.

#51

#52

Today I get the BW turbochargers in and start modifying them so they can handle more boost.

I also had a look on how the compressor wheel is build up and it a lot more advanced compared to even the latest generation of Holset billed wheels.

Also had a look @ MWE Ė Map Width Enhancement part in the compressor housing and the way the re circulate air, also a lot different to Holset.

On paper all looks better with the BW compared Holset, hope we will get lower shaft RPM @ the same boost level and a lower compressor discharge temp, cantís wait to get the data from these turbochargers.

Tomorrow they going to the machine shop to make preparations for the speed sensors, get about time they get this option as standard as the SX500 got it for some time now.

I also had a look on how the compressor wheel is build up and it a lot more advanced compared to even the latest generation of Holset billed wheels.

Also had a look @ MWE Ė Map Width Enhancement part in the compressor housing and the way the re circulate air, also a lot different to Holset.

On paper all looks better with the BW compared Holset, hope we will get lower shaft RPM @ the same boost level and a lower compressor discharge temp, cantís wait to get the data from these turbochargers.

Tomorrow they going to the machine shop to make preparations for the speed sensors, get about time they get this option as standard as the SX500 got it for some time now.

#53

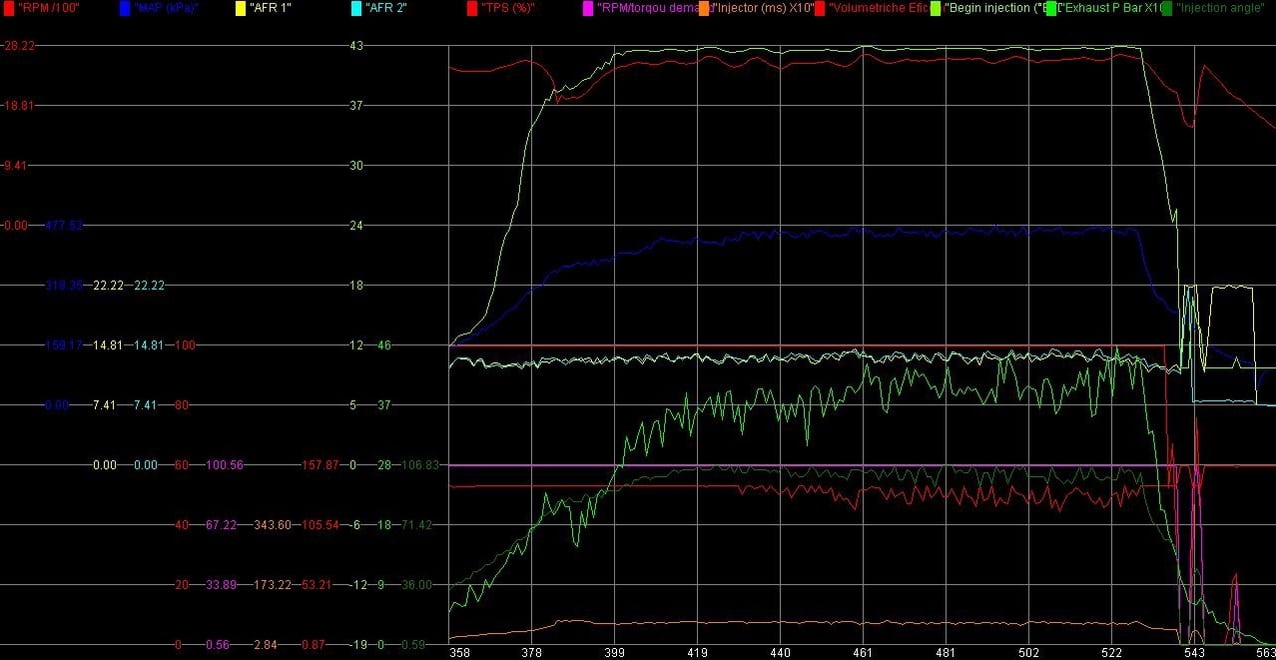

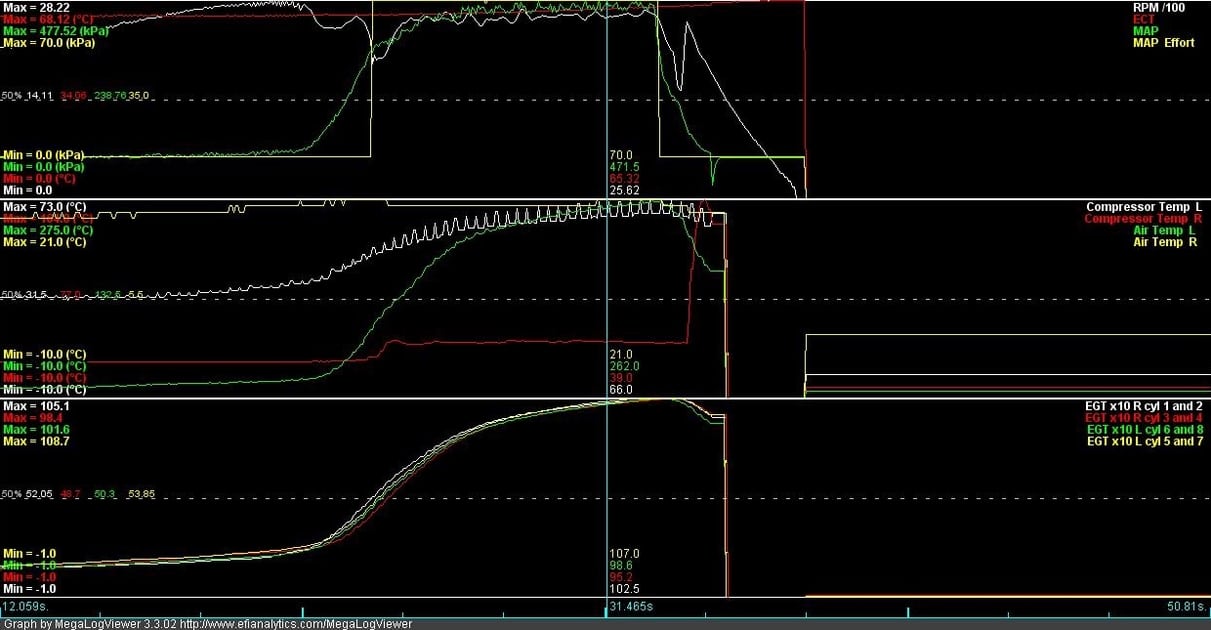

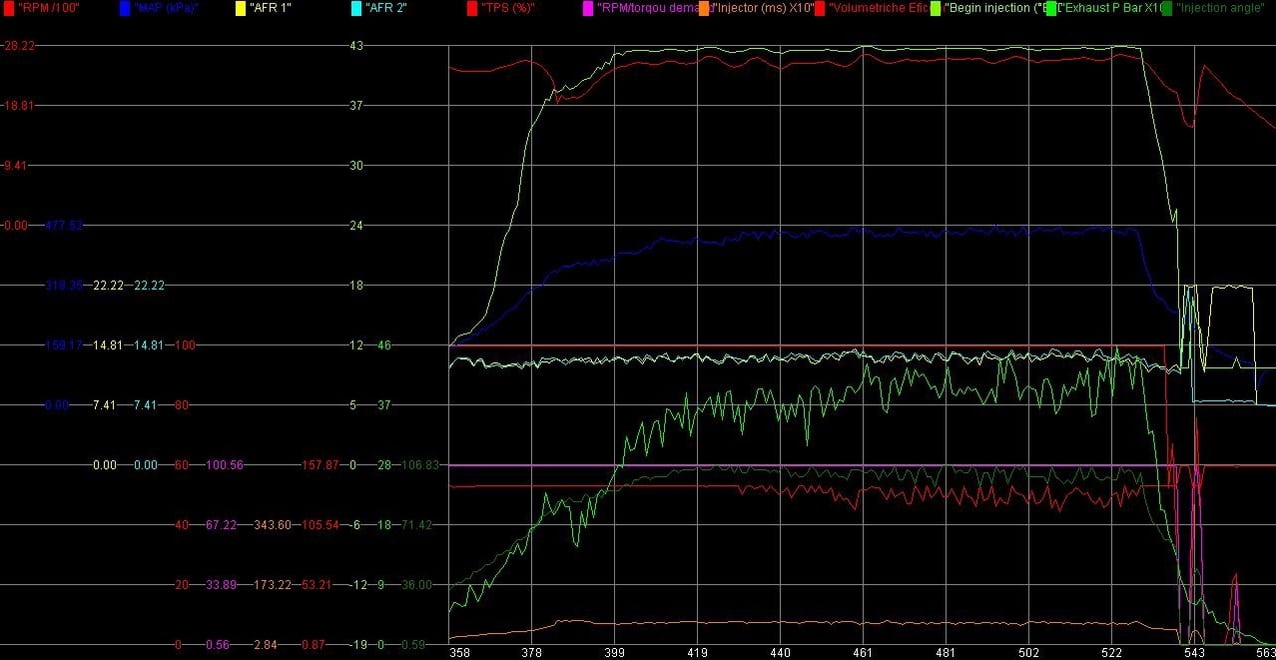

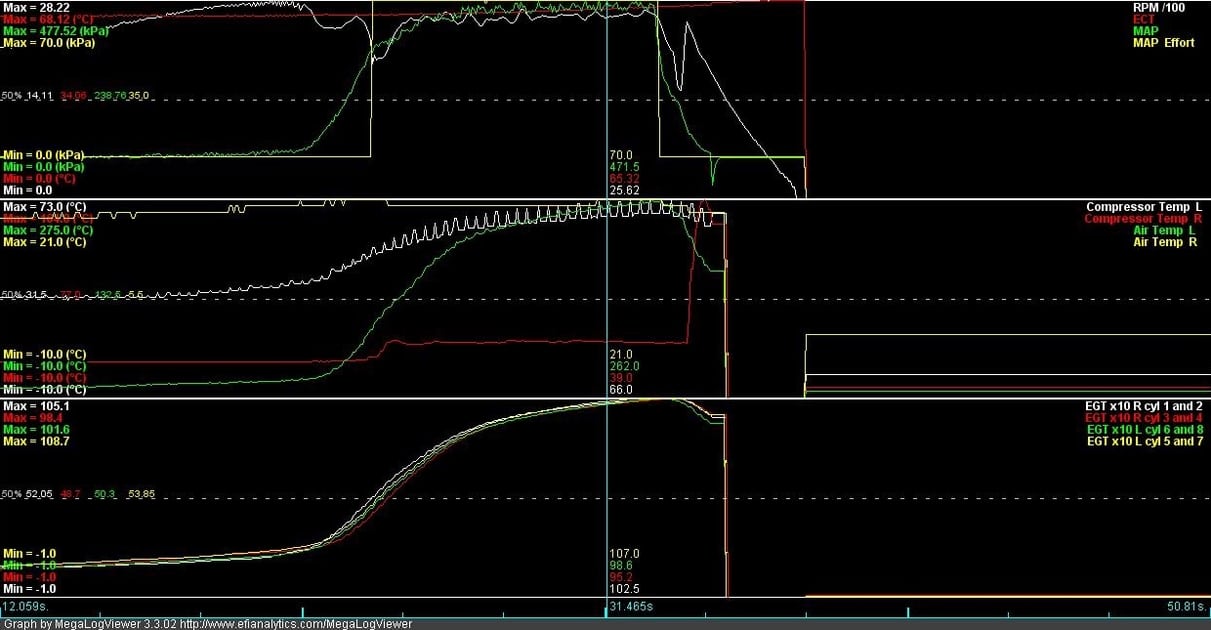

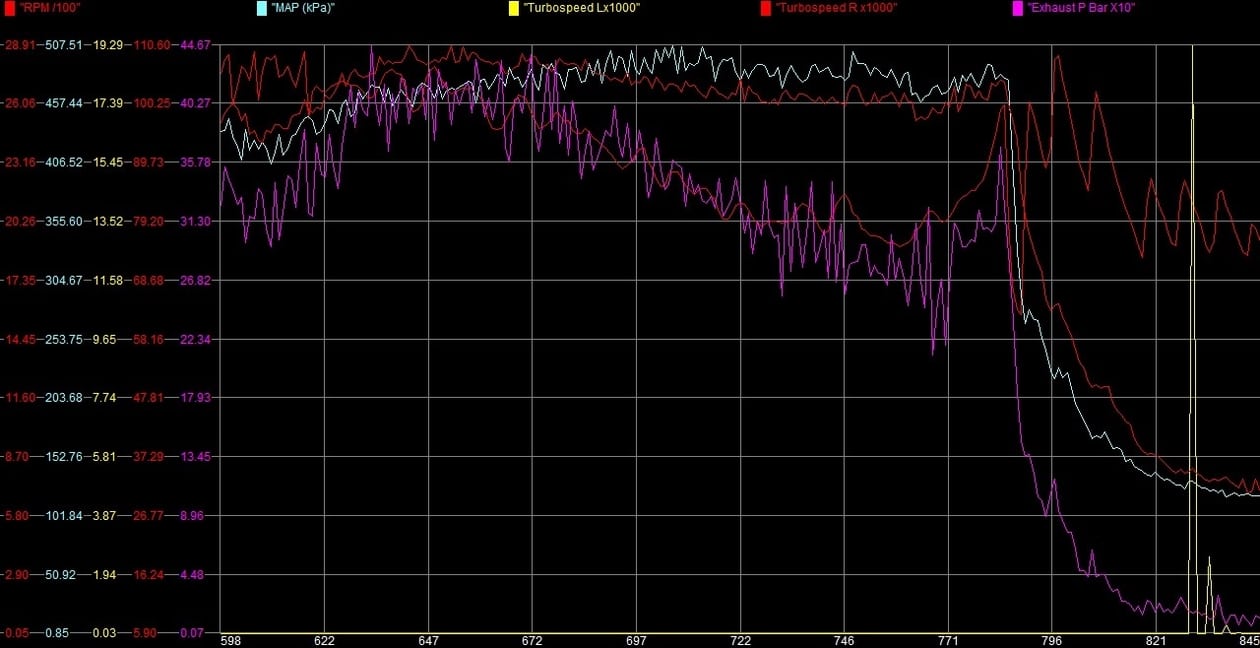

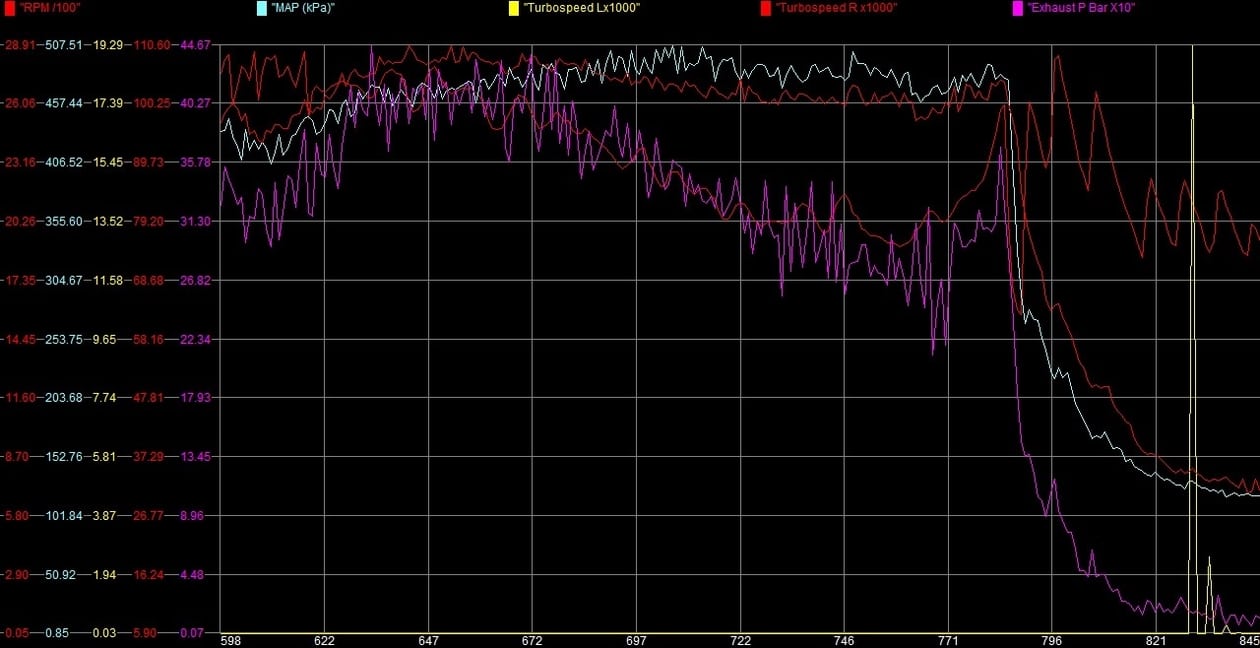

The changes to the ECU software are working great and I have good steady data to work with and set out this data in the BorgWarner matchbot.

To me itís also clear what happens if you run your turbo of the flow chard as to exhaust pressure verses boost pressure.

What I did is worked the differences on a 82 and 88mm turbine in matchbot.

Link to matchbot with a 82mm 1.25AR hot side

BorgWarner MatchBot

Link to matchbot with a 89mm 1.32AR hot side

BorgWarner MatchBot

Al do did only get number 4 place we have a load of data and information that will help us to balance the semi on stand tracks and we know what gear to take along with the rest.

We only did two runs and the first was done with the same balance setting as last year and it still proven to be ideal but the engine did not want to go down in RPM making a 2 second faster pas than the competition.

The second and final run we did go one gear up hoping still to make a full pull and also pull the engine RPM down as low as possible but we came 7 meters short dropping off boost @ 1800RPM lifting the front wheels a little off the ground even so yes we got loads of torque but lost momentum.

Pull off filmed from the front. Looks like we dropped the compressor surge line from 2100Rpm to 1800Rpm so yes Iím happy.

To me itís also clear what happens if you run your turbo of the flow chard as to exhaust pressure verses boost pressure.

What I did is worked the differences on a 82 and 88mm turbine in matchbot.

Link to matchbot with a 82mm 1.25AR hot side

BorgWarner MatchBot

Link to matchbot with a 89mm 1.32AR hot side

BorgWarner MatchBot

Al do did only get number 4 place we have a load of data and information that will help us to balance the semi on stand tracks and we know what gear to take along with the rest.

We only did two runs and the first was done with the same balance setting as last year and it still proven to be ideal but the engine did not want to go down in RPM making a 2 second faster pas than the competition.

The second and final run we did go one gear up hoping still to make a full pull and also pull the engine RPM down as low as possible but we came 7 meters short dropping off boost @ 1800RPM lifting the front wheels a little off the ground even so yes we got loads of torque but lost momentum.

Pull off filmed from the front. Looks like we dropped the compressor surge line from 2100Rpm to 1800Rpm so yes Iím happy.

#55

Loads of happy faces in the team after last night pulling event. Second place on a clay track and less than 3 meter behind the number one running an 18L engine.

Also itís the first time the engine did not stall in the low RPM but looked like we get a torque increase like you would expect as you have more valve opening time and more time to burn your fuel.

Also the balance of the truck worked out fine as we have moved more weight to the front of the truck. It can still do a small wheelie but short after the wheels are coming down.

We now run a hi 14AFR all the way and even added 10% more VE (VE as for volumetric efficiency that calculate to the amount fuel injected) and it looks like the next best step is to increase boost/airflow so turbochargers will be next to try this and will start looking in to flowing the still standard cylinder heads. We now have 305CFM and we hope to get over 400CFM and even more swirl.

Also itís the first time the engine did not stall in the low RPM but looked like we get a torque increase like you would expect as you have more valve opening time and more time to burn your fuel.

Also the balance of the truck worked out fine as we have moved more weight to the front of the truck. It can still do a small wheelie but short after the wheels are coming down.

We now run a hi 14AFR all the way and even added 10% more VE (VE as for volumetric efficiency that calculate to the amount fuel injected) and it looks like the next best step is to increase boost/airflow so turbochargers will be next to try this and will start looking in to flowing the still standard cylinder heads. We now have 305CFM and we hope to get over 400CFM and even more swirl.

#56

Yesterday we had a bit of bad luck also blowing up a turbocharger in qualification. Interesting could be if there is something in the data that indicate that something is going to happen.

The only thing I could find is the discharge temp from the compressor stays low and than jump up just before blowing up.

We here able to replace the turbocharger just under 16 minutes as we here lucky that the turbine housing was not damaged and where able to complete qualification ending up 3 place after the pull off. We here fist to make a pull and we took the wrong side of the track not able to find good traction not gaining a lot of speed.

The only thing I could find is the discharge temp from the compressor stays low and than jump up just before blowing up.

We here able to replace the turbocharger just under 16 minutes as we here lucky that the turbine housing was not damaged and where able to complete qualification ending up 3 place after the pull off. We here fist to make a pull and we took the wrong side of the track not able to find good traction not gaining a lot of speed.

#57

We got all the data from the S400X3 now but it did come with a price as we ended up with only 5 place in the last championship even taking a gear that proven to be to hi to make it to the next round.

The BW S400 is a far better turbochargers than the Holset we used in the past.

The compressor flowmap used in matchbot is the real thing as I dialled in all the data from my log file like RPM boost and a load more other data.

The BW 1.25A/R TH outflows a 32cm2 from Holset so we are a bit short on boost on the low end but we know the hi pressure injectors we going to use for the next event will give about 0,5Bar or 7 PSI more boost on a Holset with the same amount of fuel so I got good hope we will see some more boost next time but change is we going to need the 1.10A/R TH for faster boost response and not having to use the clutch to create boost @ the start of a pull.

Also the compressor dos not bark off while dropping off boost @ low RPM.

Best of all is that BorgWarner and some companies close to BorgWarner have been very help full and responsive with giving information and it looks like we are now able to build customised turbochargers al do for our engine it looks like the minor changes we made to the S400 work for now. Iím real happy that we can now step up thing in performance.

The BW S400 is a far better turbochargers than the Holset we used in the past.

The compressor flowmap used in matchbot is the real thing as I dialled in all the data from my log file like RPM boost and a load more other data.

The BW 1.25A/R TH outflows a 32cm2 from Holset so we are a bit short on boost on the low end but we know the hi pressure injectors we going to use for the next event will give about 0,5Bar or 7 PSI more boost on a Holset with the same amount of fuel so I got good hope we will see some more boost next time but change is we going to need the 1.10A/R TH for faster boost response and not having to use the clutch to create boost @ the start of a pull.

Also the compressor dos not bark off while dropping off boost @ low RPM.

Best of all is that BorgWarner and some companies close to BorgWarner have been very help full and responsive with giving information and it looks like we are now able to build customised turbochargers al do for our engine it looks like the minor changes we made to the S400 work for now. Iím real happy that we can now step up thing in performance.

#58

Yesterday I had a great conversation with a turbo expert and I was able to go over a lot of log file data trying to recover why some of our Holset turbo failed in the past.

The Holset billed wheels we used in the past are billed and not forced billed so the only benefit you will have for a short time is that the blades will flex a bit more but after and X amount of runs the alloy changes and become more brittle. It also looks like the alloy used on some billed compressor wheels is softer than the cast wheel relieving tension on the shaft assembly making it possible to rotate the compressor wheel on the shaft throwing the shaft assembly out of balance.

The most common course that we seen so many turbo damage seems to be the pressure differential @ low RPM where the boost pressure goes up and the back pressure drops a lot putting a lot of stress on the trust bearing on the compressor side and to finish it all off hitting the surge line hammering out what left on lubrication oil and friction creating a lot of heat in the shaft. On the last turbo failure we could clearly see that the back of the compressor wheel had melted and that the shaft had rotated in the trust bearing ring. After measuring a couple of broken turbine shaft it indicates that most of them snap or break around where the trust bearing is located. I think the solution to avoid these problems is to inspect and replace the trust bearing more often but is this a good solution?

What we have seen on the data log from the BorgWarner turbo with a hi flow turbine wheel is that on the hi end the pressure differential is a bit less compared to the Holset turbo but while dropping in RPM pressure differential dos not drop that hard.

HX60 low flow tubinewheel 1.5 Bar (21.7 PSI) boost to exhaust pressure

S400 hi flow tubinewheel 0,8Bar (11.6 PSI) boost to exhaust pressure.

I hope this is use full to some? have fun.

The Holset billed wheels we used in the past are billed and not forced billed so the only benefit you will have for a short time is that the blades will flex a bit more but after and X amount of runs the alloy changes and become more brittle. It also looks like the alloy used on some billed compressor wheels is softer than the cast wheel relieving tension on the shaft assembly making it possible to rotate the compressor wheel on the shaft throwing the shaft assembly out of balance.

The most common course that we seen so many turbo damage seems to be the pressure differential @ low RPM where the boost pressure goes up and the back pressure drops a lot putting a lot of stress on the trust bearing on the compressor side and to finish it all off hitting the surge line hammering out what left on lubrication oil and friction creating a lot of heat in the shaft. On the last turbo failure we could clearly see that the back of the compressor wheel had melted and that the shaft had rotated in the trust bearing ring. After measuring a couple of broken turbine shaft it indicates that most of them snap or break around where the trust bearing is located. I think the solution to avoid these problems is to inspect and replace the trust bearing more often but is this a good solution?

What we have seen on the data log from the BorgWarner turbo with a hi flow turbine wheel is that on the hi end the pressure differential is a bit less compared to the Holset turbo but while dropping in RPM pressure differential dos not drop that hard.

HX60 low flow tubinewheel 1.5 Bar (21.7 PSI) boost to exhaust pressure

S400 hi flow tubinewheel 0,8Bar (11.6 PSI) boost to exhaust pressure.

I hope this is use full to some? have fun.

#59

We have done it this time ending up in first place.

Last week we changed to the hi pressure injectors hoping that it will make the extra power needed. The last time we tested these injector we blow up a HX60 like a hand grenade more than a year ago.

Last week the driver had to work the clutch hard to get some decent boost and yesterday the truck went like never before still making close to 4 bar or 60SPI boost dropping itís EFR from a 16 to a mid 14 ending up with a EGT of exactly 951c centigrade on both cylinders banks.

So next Job is to get some more air into the engine, I think I go for one step smaller in A/R on the turbine housing as Iím dropping off boost 150RPM short of the surge line.

Last week we changed to the hi pressure injectors hoping that it will make the extra power needed. The last time we tested these injector we blow up a HX60 like a hand grenade more than a year ago.

Last week the driver had to work the clutch hard to get some decent boost and yesterday the truck went like never before still making close to 4 bar or 60SPI boost dropping itís EFR from a 16 to a mid 14 ending up with a EGT of exactly 951c centigrade on both cylinders banks.

So next Job is to get some more air into the engine, I think I go for one step smaller in A/R on the turbine housing as Iím dropping off boost 150RPM short of the surge line.

#60

Last event for the championship did not go as planed as we did not get any boost in the pull off ending up almost last losing the second place in the championship.

Yesterday we did find the problem as one of the wastegate coupling came loose ending up having not a lot of exhaust pressure and as we discover even a small leak in combination with a hi flow turbines will make it impossible to gain boost. Well lessons learned on that part.

Yesterday we did have one demo pull as we needed a good feeling of performance and also a load of data as we did make some changes to the turbochargers. We asked the pulling sled for a mega final pulloff setting and selected a hi gear and low tyre pressure and went for hoping the engine will drop to staling RPM but we did not go any lower then 2323Rpm losing some traction on the end of the pull but it looks that we gained more power than we where thinking only adding 0,3bar more boost.

Yesterday we did find the problem as one of the wastegate coupling came loose ending up having not a lot of exhaust pressure and as we discover even a small leak in combination with a hi flow turbines will make it impossible to gain boost. Well lessons learned on that part.

Yesterday we did have one demo pull as we needed a good feeling of performance and also a load of data as we did make some changes to the turbochargers. We asked the pulling sled for a mega final pulloff setting and selected a hi gear and low tyre pressure and went for hoping the engine will drop to staling RPM but we did not go any lower then 2323Rpm losing some traction on the end of the pull but it looks that we gained more power than we where thinking only adding 0,3bar more boost.