V2203 RX7 - Fate

#43

Hey Red, quick question if I may? On the FC, how far is it from the crossmember to the firewall? I'm sorta looking at FB's and FC's and wondering if the carrier oil pan might be made to fit behind the crossmember or drag link. I'm not beyond trimming the firewall for it if it's close. Thanks in advance!

I haven't measured, but I did mock it up with a cardboard box when I first got the car back. IIRC, it would be an inch or so too long to clear the crossmember with the carrier pan.

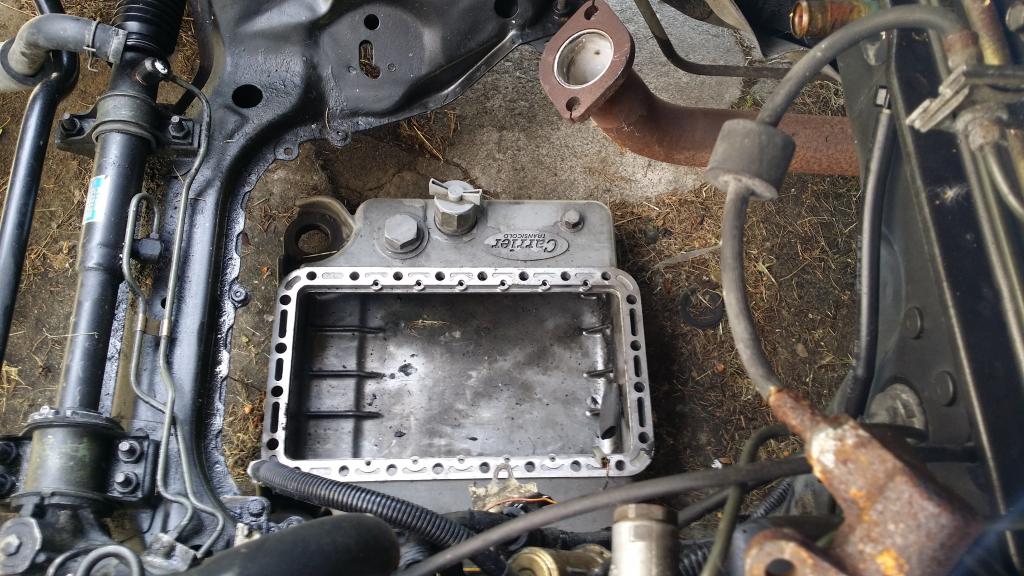

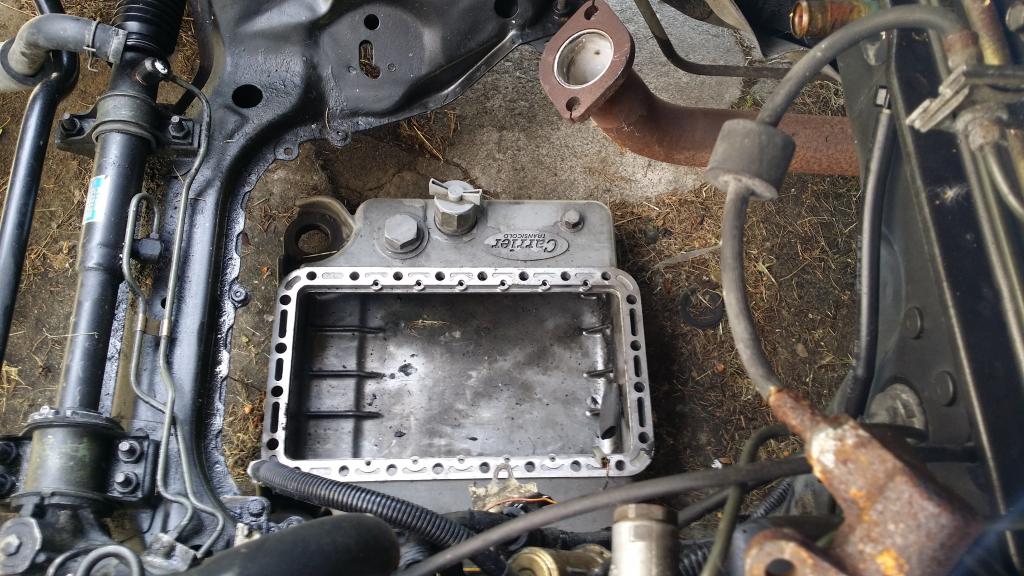

Here's a picture with the "engine" butted against the stock transmission. It's not very clear, but there was still a few inches of firewall clearance. Any other transmission will be a lot shorter, so moving it back will be beneficial or necessary anyway. If you're willing to clearance the firewall, then it MIGHT fit... A secondary consideration is how the mushroomed bottom of the pan may restrict options for exhaust routing. Hopefully I'll have some time to play with it some more and get some definite information soon.

Here is a reference picture of the empty engine bay. I need to take some more pictures. I've stripped out all of the unnecessary crap, and cleaned it since I took these. After typing all of the stuff out above, I noticed how the crossmember goes back along side the engine, and I'm starting to remember that it may be too narrow for the carrier pan farther back as well.

#44

Rangmar dropped off the new engine yesterday. 1100hrs!

I also did some fitment tests with the stock Carrier pan. It looks like it would fit if the stock mounting ears were cut off, and with some trimming to the seam on the cross member and possibly a little firewall clearancing. The distance between the firewall and the crossmember is pretty much identical to the length of the Kubota block. One big challenge to having the engine back that far would be that one of the heater core outlets come out of the firewall directly behind the engine. I'll probably just use a bobcat pan clearanced for the crossmember in front, so I can position the engine an inch or or so from the firewall.

The pictures are a little deceiving with the oil pan sitting on the ground. The rear of the pan is at, or possible a little under the edge of the firewall. the front is right at the seam for the crossmember.

I also did some fitment tests with the stock Carrier pan. It looks like it would fit if the stock mounting ears were cut off, and with some trimming to the seam on the cross member and possibly a little firewall clearancing. The distance between the firewall and the crossmember is pretty much identical to the length of the Kubota block. One big challenge to having the engine back that far would be that one of the heater core outlets come out of the firewall directly behind the engine. I'll probably just use a bobcat pan clearanced for the crossmember in front, so I can position the engine an inch or or so from the firewall.

The pictures are a little deceiving with the oil pan sitting on the ground. The rear of the pan is at, or possible a little under the edge of the firewall. the front is right at the seam for the crossmember.

#46

It looks like I'm still having trouble with my turbo adapter. The bottom of the pipe is broke away from the base all of the way around. I think I can eliminate vibration stress as a possibility this time, since the braces are fine. My theory is that heat expansion on the longer braces tore the pipe from the base. I'm ordering some 11 gauge pipe to possibly use without bracing.

#47

It looks like I'm still having trouble with my turbo adapter. The bottom of the pipe is broke away from the base all of the way around. I think I can eliminate vibration stress as a possibility this time, since the braces are fine. My theory is that heat expansion on the longer braces tore the pipe from the base. I'm ordering some 11 gauge pipe to possibly use without bracing.

#49

Since I welded Jet Air Craft I will tell you what I feel it is even though you will not believe me.

The crack as shown looks to be in the metal itself at the connection between the weld and the tubing. And it also looks as though it was done with a TIG.

I would weld it using Oxy/Acetylene as that spreads out the heat and will not make that small area brittle as in this case. Also do not force cool it. Instead just let it air cool.

The crack as shown looks to be in the metal itself at the connection between the weld and the tubing. And it also looks as though it was done with a TIG.

I would weld it using Oxy/Acetylene as that spreads out the heat and will not make that small area brittle as in this case. Also do not force cool it. Instead just let it air cool.

#50

I'm actually thinking along the same lines.

After doing some research on similar problems, it seems to be more commonly caused by contamination. That seems to be supported by the fact that the crack started right where the original crack was that we repaired, but there's no way to know for sure.

We're not set up for gas welding, but it's getting a new 11g pipe and will be meticulously cleaned before welding this time!

After doing some research on similar problems, it seems to be more commonly caused by contamination. That seems to be supported by the fact that the crack started right where the original crack was that we repaired, but there's no way to know for sure.

We're not set up for gas welding, but it's getting a new 11g pipe and will be meticulously cleaned before welding this time!