drive pressure

#12

#13

#14

#15

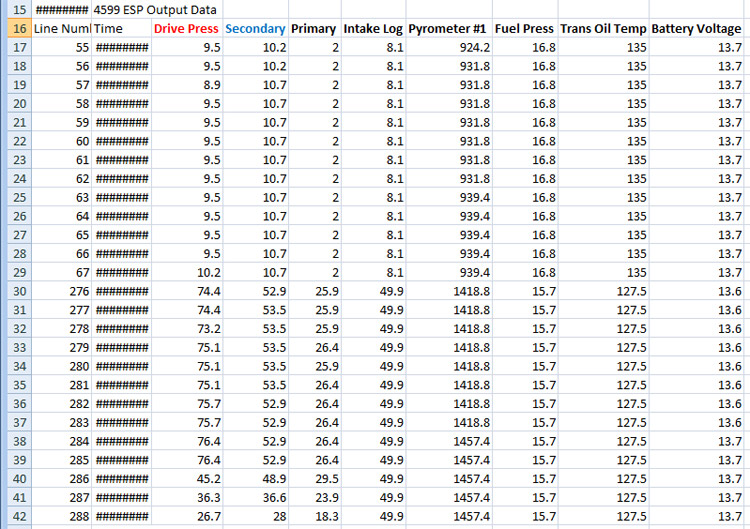

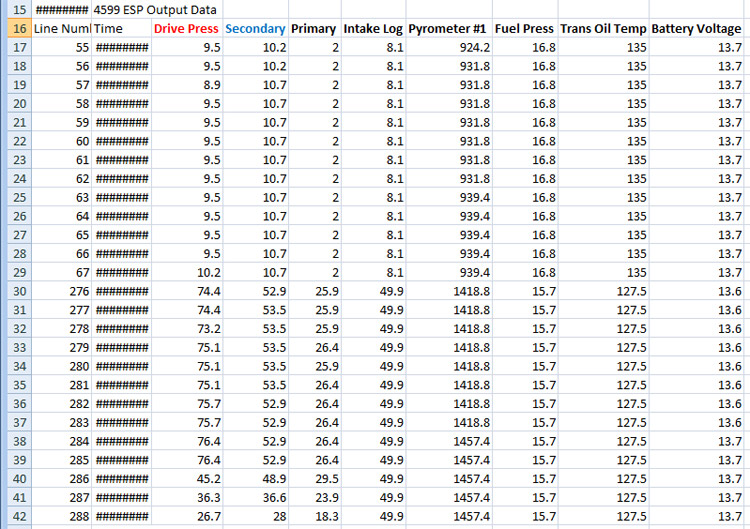

This may help illustrate what folks are describing . . . . .

This is a snippet of my DATA-logger's output. Among other stuff, I've pressure sensors reading:

(1) Exhaust gas pressure in the exhaust manifold just before it enters the secondary turbo (labeled Drive Pressure)

(2) Final boost pressure just as it leaves the secondary turbo (labeled Secondary).

Comparing those two numbers gives you the system's Drive Pressure Ratio.

The top half of the log shows me trying to maintain 10psig boost. With that, you can see a negative drive pressure ratio is possible. The bottom half shows wide open throttle (no2 only) and the 1.5 to 1 drive pressure ratio my mess currently presents.

This is a snippet of my DATA-logger's output. Among other stuff, I've pressure sensors reading:

(1) Exhaust gas pressure in the exhaust manifold just before it enters the secondary turbo (labeled Drive Pressure)

(2) Final boost pressure just as it leaves the secondary turbo (labeled Secondary).

Comparing those two numbers gives you the system's Drive Pressure Ratio.

The top half of the log shows me trying to maintain 10psig boost. With that, you can see a negative drive pressure ratio is possible. The bottom half shows wide open throttle (no2 only) and the 1.5 to 1 drive pressure ratio my mess currently presents.

#16

so what ratio is when it starts becoming a bad ratio?

---AutoMerged DoublePost---

also, what causes the drive pressures to become higher? is it bad or weak turbos being overboosted or headgasket problems or what. i guess what im saying is how would you lower your drive pressure

---AutoMerged DoublePost---

also, what causes the drive pressures to become higher? is it bad or weak turbos being overboosted or headgasket problems or what. i guess what im saying is how would you lower your drive pressure

Last edited by tltruckparts; 04-21-2010 at 10:39 PM. Reason: Automerged Doublepost

#17

To lower it would be to find that more efficient turbo, a two small and restrictive turbo would cause higher drive pressure and at the same time you are going to see high drive pressure with a to large of turbo. That exhaust gas is what has to spin up that turbo, so bigger the turbo the more drive pressure it is going to have to take. I would like to see what kind of drive pressure you are running with that HX40 compared to someone with an HX40. It would tell us more for sure.

#18

Drive pressure is the amount of force (in pounds per square inch) that is being used to spin the turbocharger. A drive-to-boost pressure ratio of 1:1 is ideal, although in reality, drive pressure is usually a bit higher than boost pressure. If a situation occurs where drive pressure far exceeds boost pressure (say, 35 psi boost, 65 psi drive pressure) then you might be looking at trouble. To imitate a high drive pressure situation, try breathing in a normal breath, then cover your mouth with your hand and exhale. That is what you're doing to your engine. High drive pressures are hard on parts and make your turbocharger much less efficient.

Too much boost can also be a problem for turbochargers. To produce more boost, turbos will spin faster, and every turbocharger has a spot where it just can't spin any faster. If you have an HX35 (found on '94-'98 1/2 Dodges) for example, it can only produce about 40 psi before overspeeding becomes a threat. If you run 45 psi of boost or more on an HX35 for any extended period of time, your turbocharger is almost sure to fail.

Too much boost can also be a problem for turbochargers. To produce more boost, turbos will spin faster, and every turbocharger has a spot where it just can't spin any faster. If you have an HX35 (found on '94-'98 1/2 Dodges) for example, it can only produce about 40 psi before overspeeding becomes a threat. If you run 45 psi of boost or more on an HX35 for any extended period of time, your turbocharger is almost sure to fail.

The following users liked this post:

jeffsqartan (09-10-2014)

#19

To lower it would be to find that more efficient turbo, a two small and restrictive turbo would cause higher drive pressure and at the same time you are going to see high drive pressure with a to large of turbo. That exhaust gas is what has to spin up that turbo, so bigger the turbo the more drive pressure it is going to have to take. I would like to see what kind of drive pressure you are running with that HX40 compared to someone with an HX40. It would tell us more for sure.

are you sure that wasnt a typo

are you sure that wasnt a typo