Installing Gauges

#2

#4

Drill, various bits, grommet to go through firewall, if you don't have a tapped port for exhaust you have to weld one on, and on the boost you have to drill and tap a hole for the fittings. Also, you need to decide if you want to put your pyro pre turbo or post turbo. Post turbo is easier, but be aware it is about 300 degrees cooler when you look at the temp post turbo. Not much to it really, just chasing some tubes and wires around and drilling a few holes!

#5

#6

Drill, various bits, grommet to go through firewall, if you don't have a tapped port for exhaust you have to weld one on, and on the boost you have to drill and tap a hole for the fittings. Also, you need to decide if you want to put your pyro pre turbo or post turbo. Post turbo is easier, but be aware it is about 300 degrees cooler when you look at the temp post turbo. Not much to it really, just chasing some tubes and wires around and drilling a few holes!

then put it back together

then put it back together

#8

There is no need to drill any holes in the firewall when installing guages - there is a huge grommet there already (at least there is on my 98 and 2001 trucks).

#9

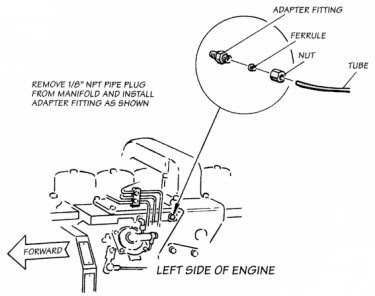

first you dont weld a port on your exhaust you drill and tap it were the 6 banks come together. secound you dont drill and tap anything on your intake to mount the boost guage there is already a 1/8"NPT plug in the side of the manifold between the #2 and #3 cylander, third its harder to drill post turbo because the cowl is in the way for of the drill which its better to do pre turbo anyway. separated the turbo 1" away from the exhast maniflod, put a rag between the two, drill/tap, start wngine with rag in there only for a few secounds withought igniting the rag then put it back together

then put it back together

then put it back together

then put it back together

Boost Guage:

You can also drill and tap the intake horn but why bother?

#10