High RPM Tuning Advice ?

#1

Hi all new bombers member here looking for some high RPM tuning suggestions.

I own the first Duramax powered boat built by PPE a few years back. She has gone from a SEMA show trailer queen to a daily driver / weekend racer since my purchase. Many upgrades and changes from the original build back in 07. Still running the LLY block and fuel system, but about everything else has been updated after a couple meltdowns due to an oil restriction issue.

What I have now is a 16.5:1 stock rod LLY with PPE manifolds, 3" intake, 4094R turbo, 50% over injectors and all the typical fuel system mods along with a lift pump. Tuning is via EFI with DSP5 options written by a well respected Dmax tuner. Runs great now, gets crazy fuel economy, and has yet to see a big block Chevy or bass boat that could pull away from it. So what else could you want, right? To break 100mph with a diesel to be exact...

Currently she is propped out to the max and pulls great up to about 3600rpm at around 85-90mph. Then hits a wall, like it's out of camshaft power or something. It needs to sustain 4000-4200 to break that 100mph barrier. Closest I've been was about 95 in salt water [which has less resistance] on the original PPE setup a couple years back. All our new mods have greatly improved mid-range power but not helped improve on the top end. She is burning pretty clean up top, not rolling coal like hooked to a sled or anything.

What's missing here to move this power range up a few hundred rpm? My best tune option is running 26deg timing, 2000us pulse at 102mm3 when she tops out at 3600. Boost is not tunable but is steady at 32psi and calculated load is only about 75%. With a stock GM cal she peaks out at 3300, so the added timing and fuel is only gaining me 300 rev's. I've tried bumping the pulse width up to 2250 and it only added to EGT's, which are already in the 1500F range up top. It's holding decent fuel pressure [within 1000 of requested] but when testing the 2250us tune it started tailing off after a few seconds.

So what you guys think?? More timing advance, fuel, or both? If it needs more fuel, gonna need to mod the pump and metering valve first. More air would require a new charger or trim change. I also have a water/methanol kit that's yet to be added in. But would like to hear from someone spinning 4k plus loaded before I make any major changes. Everything in EFI looks good against logging, but anyone interested is welcome to review it. Apologies for the length here.

Thanks

-K

I own the first Duramax powered boat built by PPE a few years back. She has gone from a SEMA show trailer queen to a daily driver / weekend racer since my purchase. Many upgrades and changes from the original build back in 07. Still running the LLY block and fuel system, but about everything else has been updated after a couple meltdowns due to an oil restriction issue.

What I have now is a 16.5:1 stock rod LLY with PPE manifolds, 3" intake, 4094R turbo, 50% over injectors and all the typical fuel system mods along with a lift pump. Tuning is via EFI with DSP5 options written by a well respected Dmax tuner. Runs great now, gets crazy fuel economy, and has yet to see a big block Chevy or bass boat that could pull away from it. So what else could you want, right? To break 100mph with a diesel to be exact...

Currently she is propped out to the max and pulls great up to about 3600rpm at around 85-90mph. Then hits a wall, like it's out of camshaft power or something. It needs to sustain 4000-4200 to break that 100mph barrier. Closest I've been was about 95 in salt water [which has less resistance] on the original PPE setup a couple years back. All our new mods have greatly improved mid-range power but not helped improve on the top end. She is burning pretty clean up top, not rolling coal like hooked to a sled or anything.

What's missing here to move this power range up a few hundred rpm? My best tune option is running 26deg timing, 2000us pulse at 102mm3 when she tops out at 3600. Boost is not tunable but is steady at 32psi and calculated load is only about 75%. With a stock GM cal she peaks out at 3300, so the added timing and fuel is only gaining me 300 rev's. I've tried bumping the pulse width up to 2250 and it only added to EGT's, which are already in the 1500F range up top. It's holding decent fuel pressure [within 1000 of requested] but when testing the 2250us tune it started tailing off after a few seconds.

So what you guys think?? More timing advance, fuel, or both? If it needs more fuel, gonna need to mod the pump and metering valve first. More air would require a new charger or trim change. I also have a water/methanol kit that's yet to be added in. But would like to hear from someone spinning 4k plus loaded before I make any major changes. Everything in EFI looks good against logging, but anyone interested is welcome to review it. Apologies for the length here.

Thanks

-K

Last edited by kidturbo; 08-14-2012 at 03:51 AM.

#2

it sounds like you are running out of turbo. have you been monitoring drive pressure for it? even though its a non gated fixed geometry turbo spinning that kind of rpms and getting 32 psi out of it you are going to need some adjustments. the turbo can flow more air than that so increasing boost by adding more fuel will get you there. Are you running a single cp3? is it a stock lly cp3?

adding timing will lower egts of course you probably know that. timing is kinda high for that kind of pulse width ( i tune differently) but your guy seems to know what he is going though so i wont doubt him there is more than one way to make horse power.

Adding water injection will drop the egts a good amount though so you could in turn add more fuel or just run water meth. me personally i would probably just run water first and see how much fuel can be flowed out that cp3 first then add meth or upgrade the pump.

how bad was the smoke and the engine knock when running the 2250 us pulse? adding timing will help out clearing the smoke and lowering the egts. how is your rail pressure holding up? are you running 23 or 26k psi?

ive got a million more questions since i do efi live tuning too and im always trying to squeeze a little more power out of mine as well

and im always trying to squeeze a little more power out of mine as well

adding timing will lower egts of course you probably know that. timing is kinda high for that kind of pulse width ( i tune differently) but your guy seems to know what he is going though so i wont doubt him there is more than one way to make horse power.

Adding water injection will drop the egts a good amount though so you could in turn add more fuel or just run water meth. me personally i would probably just run water first and see how much fuel can be flowed out that cp3 first then add meth or upgrade the pump.

how bad was the smoke and the engine knock when running the 2250 us pulse? adding timing will help out clearing the smoke and lowering the egts. how is your rail pressure holding up? are you running 23 or 26k psi?

ive got a million more questions since i do efi live tuning too

and im always trying to squeeze a little more power out of mine as well

and im always trying to squeeze a little more power out of mine as well

#3

#4

Pump is a single LLY CP3 with the bigger orifice fittings done. Rail inlet fittings were upgraded with the PPE primary inlet and we swapped the larger factory primary over to the second side rail. Of course it has the bypass blocked off too.

On the turbo side it's fed with a short 4" tube and velocity stack, exits into 3" mandrel bent tubes, water to air cooler, and custom 3" intake. Recently added the intake and longer tubes, that pepped it up a good bit mid-range.

Haven't had a chance to check the drive pressure yet, but have a spare test port so guess I could take reading on that. Most people I've spoke with don't like that turbo, but it's what I have to work with for now. When I added the extra PW I didn't notice and knock, but I left the timing alone for the test. She did make a little more boost, maybe .5 or so before EGT's jumped to 1600 and I backed out.

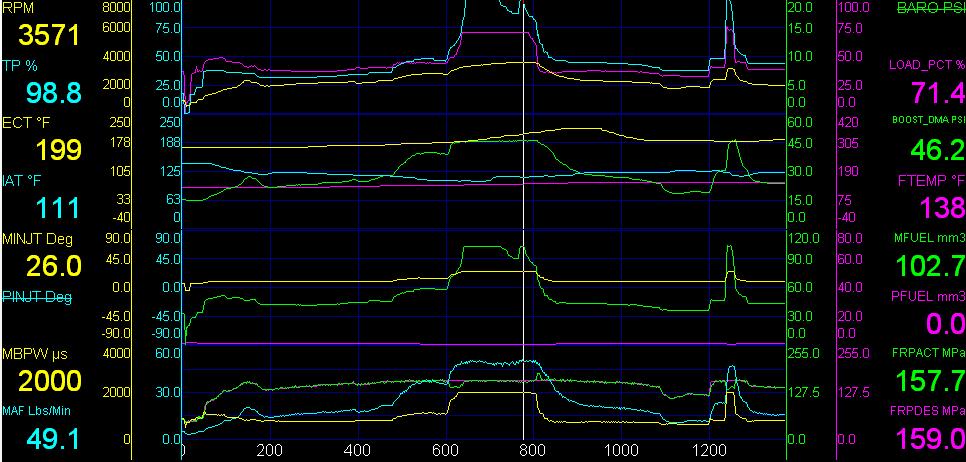

Here is a screenshot of the data logged showing where she tops out right now on the 2000us tune. Also a video of 50% throttle run from last year.

-K

On the turbo side it's fed with a short 4" tube and velocity stack, exits into 3" mandrel bent tubes, water to air cooler, and custom 3" intake. Recently added the intake and longer tubes, that pepped it up a good bit mid-range.

Haven't had a chance to check the drive pressure yet, but have a spare test port so guess I could take reading on that. Most people I've spoke with don't like that turbo, but it's what I have to work with for now. When I added the extra PW I didn't notice and knock, but I left the timing alone for the test. She did make a little more boost, maybe .5 or so before EGT's jumped to 1600 and I backed out.

Here is a screenshot of the data logged showing where she tops out right now on the 2000us tune. Also a video of 50% throttle run from last year.

-K

Last edited by kidturbo; 08-14-2012 at 01:07 PM.

#5

your timing seems pretty static over a broad range of rpms.

the power you're seeking you are gonna get some high egt's unless you add more air or inject water. its hard to avoid. i bury my egt gauge on a 1/4 mile pass. but that was wit a stock turbo.

when you say bigger orfii on the cp3 so you mean modded regulator or a 1/2 fuel fitting.

the power you're seeking you are gonna get some high egt's unless you add more air or inject water. its hard to avoid. i bury my egt gauge on a 1/4 mile pass. but that was wit a stock turbo.

when you say bigger orfii on the cp3 so you mean modded regulator or a 1/2 fuel fitting.

#6

I agree we gotta get more air along with the fuel cause I just get rolling good in a 1/4 mile...

-K

#7

No just the inlet and outlet fittings on the pump. Regulator is stock, actually just replaced it last fall so I have a spare to cut on and think that's my next upgrade. I also have some logs showing a pressure drop when I added the pulse width, she fell off to about 140mpa.

I agree we gotta get more air along with the fuel cause I just get rolling good in a 1/4 mile...

-K

I agree we gotta get more air along with the fuel cause I just get rolling good in a 1/4 mile...

-K

https://www.dieselbombers.com/chevy-...l-fitting.html

modding the cp3 would be a good idea. you could either get a bag of parts or do it yourself.

you can mod the regulator and also modify the gear pump on the back of the cp3.

#8

No just the inlet and outlet fittings on the pump. Regulator is stock, actually just replaced it last fall so I have a spare to cut on and think that's my next upgrade. I also have some logs showing a pressure drop when I added the pulse width, she fell off to about 140mpa.

I agree we gotta get more air along with the fuel cause I just get rolling good in a 1/4 mile...

-K

I agree we gotta get more air along with the fuel cause I just get rolling good in a 1/4 mile...

-K

At 3500 rpms and a 2000uS pulse the injectors are open for 42 degrees of crank angle rotation. on paper, the real life numbers are different because there is a few micro seconds delay opening and closing the injectors.

if you have 26* timing you have 61% of the injection pulse before tdc.

i suggest getting that water injection put on and lowering the egts.

#9

Exactly the same numbers I came up with using a timing calculator, was unsure of the lag offset amount. Looks like we will add the water and see how she does before jumping up the fuel and timing any further.

At least you verified my view, she is running about tapped out, or safely restrained....

Thanks

-K

---AutoMerged DoublePost---

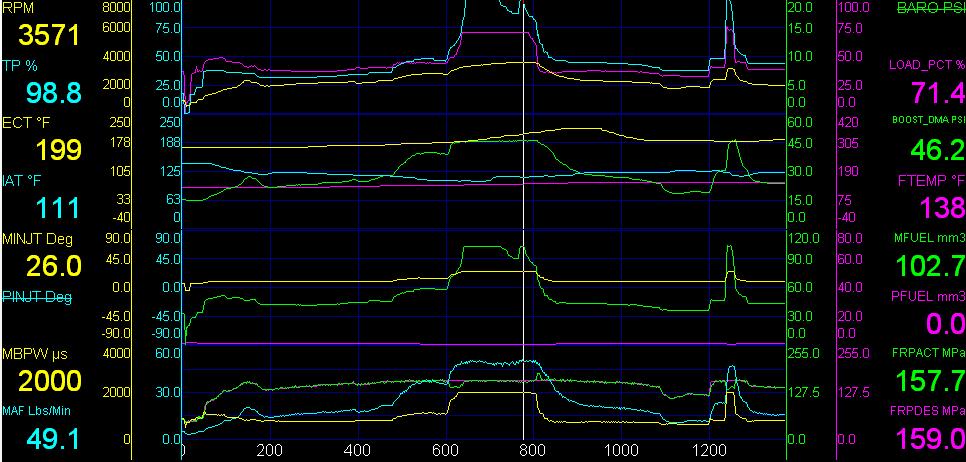

Here is a log shot of the 2250us pulse changes. You can see where fuel pressure falls off at WOT then started to recover but couldn't match requested. Once boating season winds down I'll mod the regulator and port the mechanical lift.

Has anyone ever done a write up on deleting the mechanical lift pump? My E320 CDI uses a CP3 with in tank lift, as do several other common rail setups. I find it kinda redundant to push thru a mechanical, when they've had a tenancy to fail and take the main CP3 pistons out with them..

Cheers,

-K

At least you verified my view, she is running about tapped out, or safely restrained....

Thanks

-K

---AutoMerged DoublePost---

Here is a log shot of the 2250us pulse changes. You can see where fuel pressure falls off at WOT then started to recover but couldn't match requested. Once boating season winds down I'll mod the regulator and port the mechanical lift.

Has anyone ever done a write up on deleting the mechanical lift pump? My E320 CDI uses a CP3 with in tank lift, as do several other common rail setups. I find it kinda redundant to push thru a mechanical, when they've had a tenancy to fail and take the main CP3 pistons out with them..

Cheers,

-K

Last edited by kidturbo; 08-14-2012 at 10:10 PM. Reason: Automerged Doublepost

#10

yikes. well going from a 2000 to a 2250 pulse with 50% overs is like going from a 3000 to a 3375 pulse with stock injectors and that is huge.

you could try a 2133 pulse and hopefully it wont drop down so much, its similar to running a 3200 pulse on stock.

hmmm the mechanical lift pump also serves a purpose in the cp3. it force feeds the fuel in into the three cylinders into the cp3 with some high pressure fuel. ive got pics i can show of a cp3. ill take it all the way apart so you can see the internals ill document it for ya

what a/r is the turbine housing on the 4094? and yeah you really cant to much more with the fuel, you could maybe try taking a little less fuel from the middle part of the rpm scale so there would be some left at the top

you could try a 2133 pulse and hopefully it wont drop down so much, its similar to running a 3200 pulse on stock.

hmmm the mechanical lift pump also serves a purpose in the cp3. it force feeds the fuel in into the three cylinders into the cp3 with some high pressure fuel. ive got pics i can show of a cp3. ill take it all the way apart so you can see the internals ill document it for ya

what a/r is the turbine housing on the 4094? and yeah you really cant to much more with the fuel, you could maybe try taking a little less fuel from the middle part of the rpm scale so there would be some left at the top