1999 ranger yanmar to kubota v2203 swap

#21

#22

I do not know much if anything about the Kubota V2203 but I do know that Big Trucks with there Turbo Diesels like to be loaded down a bit. I think that is where the Turbo Diesel really shines over a gas engine.

---AutoMerged DoublePost---

Just had to say you did one Heck of a Good Job.

I will be getting an adapter plate soon for my swap. And to be sure there will be lots of questions to come .

.

As some members may know I tend to be well a bit HYPER when I am excited about a project so I will apologize before hand if I seem to get a little oh NUTS .

.

But I am learning to take one thing at a time. So first will be mating the trans to the engine then move on from there.

---AutoMerged DoublePost---

Just had to say you did one Heck of a Good Job.

I will be getting an adapter plate soon for my swap. And to be sure there will be lots of questions to come

.

. As some members may know I tend to be well a bit HYPER when I am excited about a project so I will apologize before hand if I seem to get a little oh NUTS

.

.

But I am learning to take one thing at a time. So first will be mating the trans to the engine then move on from there.

Last edited by JesterGrin_1; 11-03-2013 at 03:02 PM. Reason: Automerged Doublepost

#23

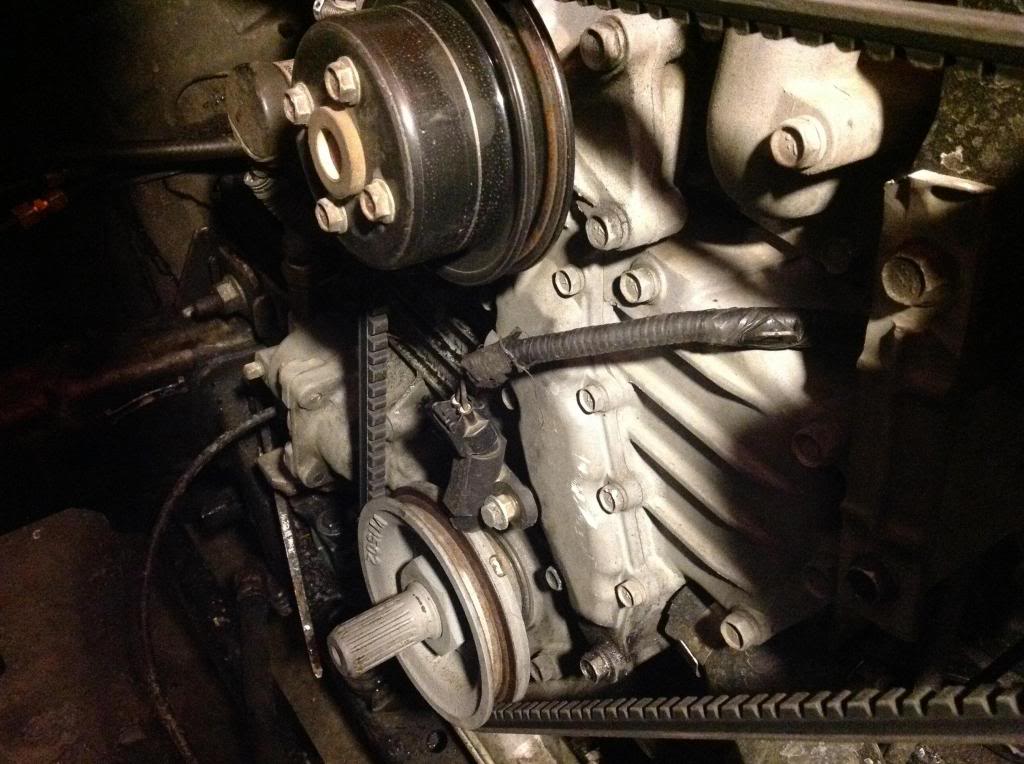

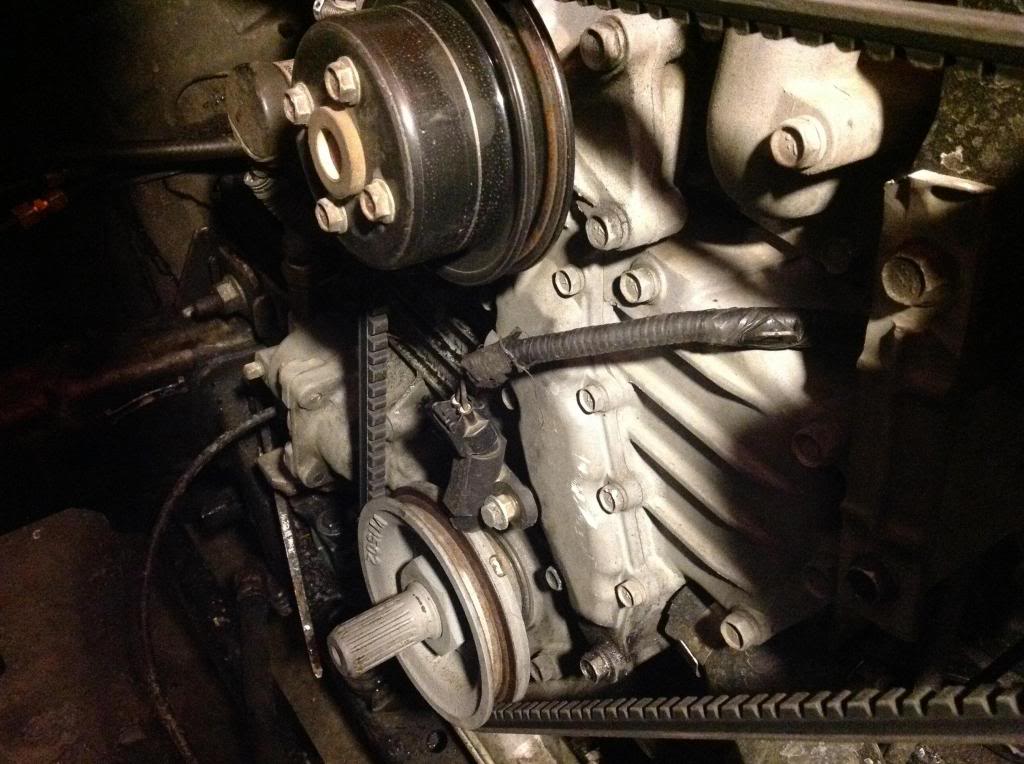

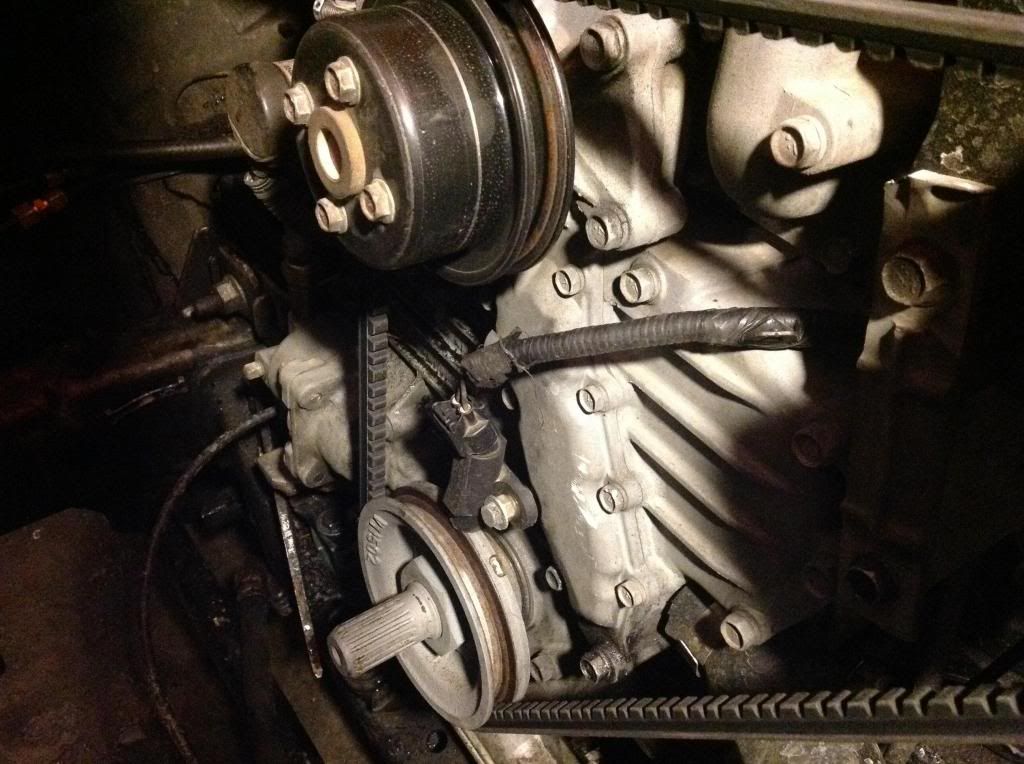

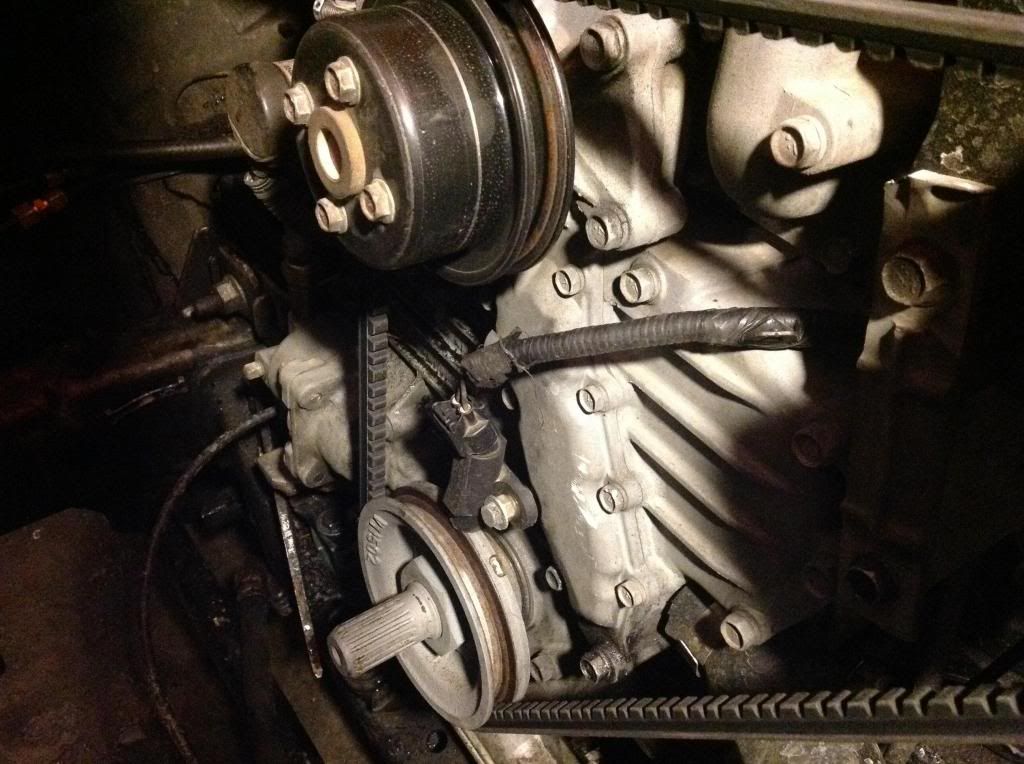

I appreciate the complement. Hera are some pics fte ask me to post I have a working tach now thanks to some redneck engineering fte had the idea with his and I adapted it to mine.

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

I used the factory crank sensor and hard wired it directly to the signal wire on the tach on the back of the gauge cluster I then measured and drilled 3 holes on the crank pulley (2 for a 4cyl 3 for a 6cyl) and a switched positive to the crank sensor

ignore the airbag light I have to go through a dot inspection before I can remove it and add 8% for my tires so its at 60

---AutoMerged DoublePost---

I have found my first negative about the kubota

It is lighter in the front now so it's a bit squirrely if I'm not careful and its a bit of a hand full trying to tame that much torque at 1500 rpm. But I think a winch in the front and a lighter foot will solve the issues

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

I used the factory crank sensor and hard wired it directly to the signal wire on the tach on the back of the gauge cluster I then measured and drilled 3 holes on the crank pulley (2 for a 4cyl 3 for a 6cyl) and a switched positive to the crank sensor

ignore the airbag light I have to go through a dot inspection before I can remove it and add 8% for my tires so its at 60

---AutoMerged DoublePost---

I have found my first negative about the kubota

It is lighter in the front now so it's a bit squirrely if I'm not careful and its a bit of a hand full trying to tame that much torque at 1500 rpm. But I think a winch in the front and a lighter foot will solve the issues

Last edited by Rangmar; 11-03-2013 at 09:50 PM. Reason: Automerged Doublepost

#25

great Idea for the tach. The holes are related to the Original engine 3 holes if you removed a 6 cyl, and 2 holes if you removed a 4cyl??? and just 12 volts ignition switched to the tack pickup. but not going through the ECM?

Also what did you guys do for a pilot bearing on trans to flywheel?

Also what did you guys do for a pilot bearing on trans to flywheel?

#26

#27

Did you make a bushing for the pilot bearing or bore out the flywheel. What clearance on the bearing. I guess I can just copy the clearance from what it comes off of. I hope to pull the engine and trans out of the jeep the middle of this week, The Kubota accessory drive is almost finished. I guess I should start my own build thread

thanks for the info so far

thanks for the info so far

#28

I appreciate the complement. Hera are some pics fte ask me to post I have a working tach now thanks to some redneck engineering fte had the idea with his and I adapted it to mine.

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

I used the factory crank sensor and hard wired it directly to the signal wire on the tach on the back of the gauge cluster I then measured and drilled 3 holes on the crank pulley (2 for a 4cyl 3 for a 6cyl) and a switched positive to the crank sensor

ignore the airbag light I have to go through a dot inspection before I can remove it and add 8% for my tires so its at 60

---AutoMerged DoublePost---

I have found my first negative about the kubota

It is lighter in the front now so it's a bit squirrely if I'm not careful and its a bit of a hand full trying to tame that much torque at 1500 rpm. But I think a winch in the front and a lighter foot will solve the issues

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

http://i1337.photobucket.com/albums/o673/Ethanolsen77/image_zps681c650c.jpg

I used the factory crank sensor and hard wired it directly to the signal wire on the tach on the back of the gauge cluster I then measured and drilled 3 holes on the crank pulley (2 for a 4cyl 3 for a 6cyl) and a switched positive to the crank sensor

ignore the airbag light I have to go through a dot inspection before I can remove it and add 8% for my tires so its at 60

---AutoMerged DoublePost---

I have found my first negative about the kubota

It is lighter in the front now so it's a bit squirrely if I'm not careful and its a bit of a hand full trying to tame that much torque at 1500 rpm. But I think a winch in the front and a lighter foot will solve the issues

But then again I am From and In South TEXAS

But then again I am From and In South TEXAS  . We just Melt.

. We just Melt. All I know is after all of the reading I am doing I will still need to ask lots of questions. Great idea on the Tach. But since my truck has a distributor and not a sensor I will have to figure out something else for all of the gauges that I will need. As I would like to have EGT,Tach and of course Boost.

I forgot to add that it is not a Compliment it is a FACT. Very nice job.

Last edited by JesterGrin_1; 11-04-2013 at 03:05 AM.

#30

The tach set-up we used will work on older rigs as well. The reason we went off the back of the guage is to bypass the ECU. I used an ABS sensor, any two wire one will work, or a crank trigger, they work the same. On older units with distributers will be less complicated, all you need to do is hook the tach wire that came off the dist. and hook it to one of the two wires on the sensor, the other to 12v.