another om617 into 98 jeep tj

#11

and driving.

and driving. and yours (and mine) concern for the motor mounts turned out to be for naught. the vibrations arnt bad at all. even with the ic pipe off, its got some good pep

and yours (and mine) concern for the motor mounts turned out to be for naught. the vibrations arnt bad at all. even with the ic pipe off, its got some good pep

tach dont work

need to investigate this further

need to investigate this furtherthe one time i looked, the alt was charging, ill have to watch it more

need to bead roll my ic pipes, popped one off

needs a muffler....

the solenoid i used for the engine kill works perfectly, except it holds the vacuum when i go to start back up and wont allow it to start. need to figure out how to vent that.

#12

Congrats on the driver, Burn a tiny hole in the vacuum fitting...

it might not be the coolest way to shut down a benz, but I used the jeeps OE vapor canister purge solenoid, and then I burned a very small hole in one of the rubber vacuum connectors, in the shutdown side, The vacuum overcomes the leak to shut down, then bleeds off to restart. that works, but still takes a second or 2, too both shut down; and to bleed the shutdown vacuum for a restart.

there are lots and lots of different styles of solenoid vacuum valves, There are some that are exactly designed to work and vent, with no calibrated bleed orifice required, I did my best to buy the correct style, but I got it wrong, so I used what was in the shop.

for the tach, are the rest of your instruments working? do you have any kind of a a cam signal? crank signal?.

have you seen the beaders that people make from heavy duty wire crimpers pliers?

congrats on the driver again

have fun

it might not be the coolest way to shut down a benz, but I used the jeeps OE vapor canister purge solenoid, and then I burned a very small hole in one of the rubber vacuum connectors, in the shutdown side, The vacuum overcomes the leak to shut down, then bleeds off to restart. that works, but still takes a second or 2, too both shut down; and to bleed the shutdown vacuum for a restart.

there are lots and lots of different styles of solenoid vacuum valves, There are some that are exactly designed to work and vent, with no calibrated bleed orifice required, I did my best to buy the correct style, but I got it wrong, so I used what was in the shop.

for the tach, are the rest of your instruments working? do you have any kind of a a cam signal? crank signal?.

have you seen the beaders that people make from heavy duty wire crimpers pliers?

congrats on the driver again

have fun

#13

Congrats on the driver, Burn a tiny hole in the vacuum fitting...

it might not be the coolest way to shut down a benz, but I used the jeeps OE vapor canister purge solenoid, and then I burned a very small hole in one of the rubber vacuum connectors, in the shutdown side, The vacuum overcomes the leak to shut down, then bleeds off to restart. that works, but still takes a second or 2, too both shut down; and to bleed the shutdown vacuum for a restart.

there are lots and lots of different styles of solenoid vacuum valves, There are some that are exactly designed to work and vent, with no calibrated bleed orifice required, I did my best to buy the correct style, but I got it wrong, so I used what was in the shop.

for the tach, are the rest of your instruments working? do you have any kind of a a cam signal? crank signal?.

have you seen the beaders that people make from heavy duty wire crimpers pliers?

congrats on the driver again

have fun

it might not be the coolest way to shut down a benz, but I used the jeeps OE vapor canister purge solenoid, and then I burned a very small hole in one of the rubber vacuum connectors, in the shutdown side, The vacuum overcomes the leak to shut down, then bleeds off to restart. that works, but still takes a second or 2, too both shut down; and to bleed the shutdown vacuum for a restart.

there are lots and lots of different styles of solenoid vacuum valves, There are some that are exactly designed to work and vent, with no calibrated bleed orifice required, I did my best to buy the correct style, but I got it wrong, so I used what was in the shop.

for the tach, are the rest of your instruments working? do you have any kind of a a cam signal? crank signal?.

have you seen the beaders that people make from heavy duty wire crimpers pliers?

congrats on the driver again

have fun

a buddy came over this am with his bead roller so that problem is fixed. ill work on some of these other problems later today. dad wants to go see fate of the furious

#14

although the Saab AL129X is "self exciting" you will really have to rev it to get it going (2700-3300rpm) and your ECM will throw the charge light by then if you're still using it. The field line is the way to go. If you haven't already bought the Saab alt I have found a much better option.

i had to really pay attention to the vibrations from the motor mounts today, cause they arnt noticeable over a stock engine. so, happy with the motor mounts. also installed the new wheels and tires today, and fixed a couple clearance issues.

and i think i missed it, you started with a red xj and ended with a bluey one...what happened to the red one?

#15

#16

the solenoid i used for the engine kill works perfectly, except it holds the vacuum when i go to start back up and wont allow it to start. need to figure out how to vent that.[/QUOTE]

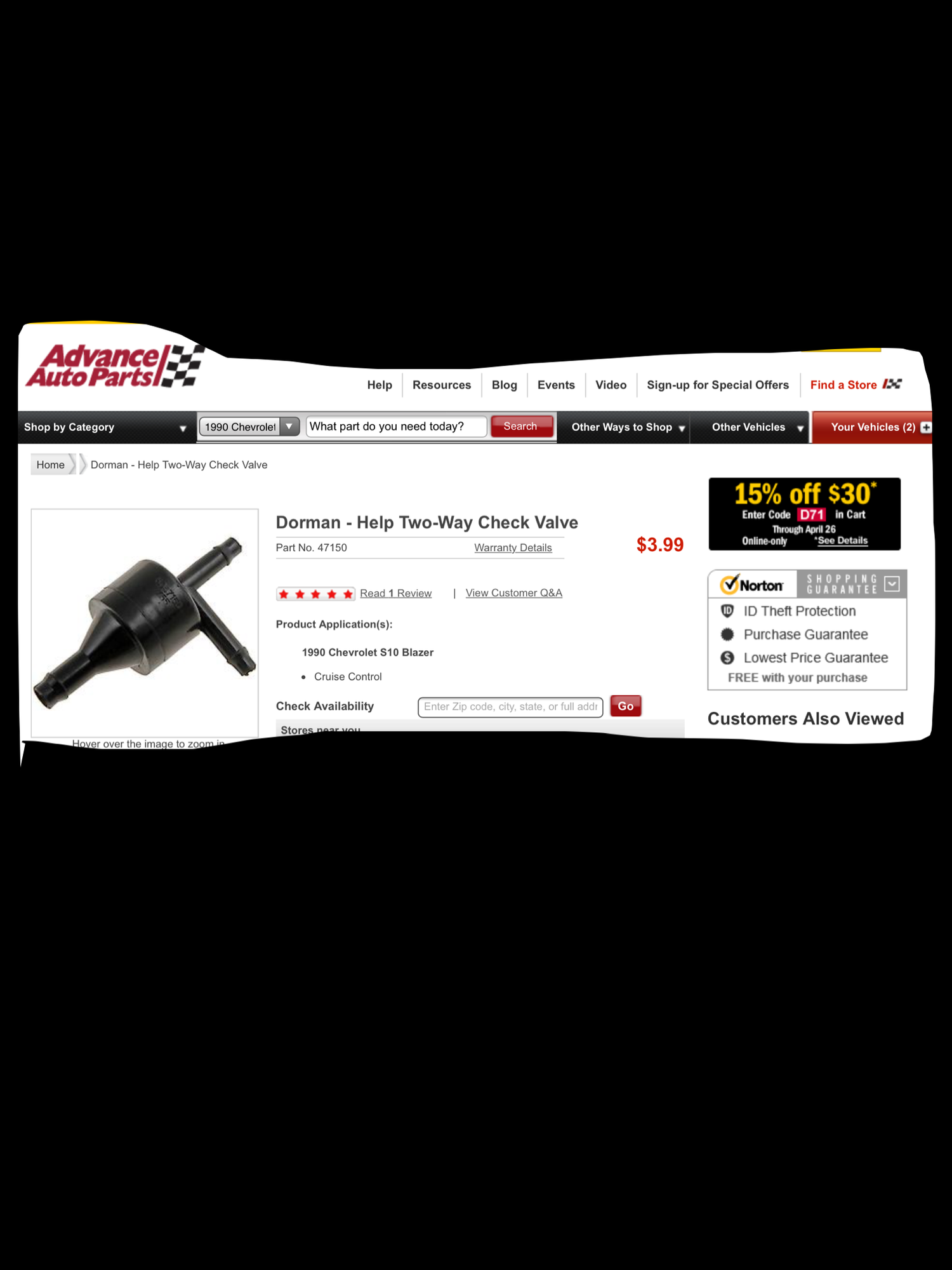

you using the wrong vac solinoid, I just figured this out this morning myself and posted on my question thread.

I used the vac switch on the left , and it initally worked on my MW pump, but did not work on my M pump, I switched this morning to the metal round vac switch on the right and it works great!

the green thing on the right is a mercedes vac check valve there are lots on the car,

hpe this helps

you using the wrong vac solinoid, I just figured this out this morning myself and posted on my question thread.

I used the vac switch on the left , and it initally worked on my MW pump, but did not work on my M pump, I switched this morning to the metal round vac switch on the right and it works great!

the green thing on the right is a mercedes vac check valve there are lots on the car,

hpe this helps

#17

I used the vac switch on the left , and it initally worked on my MW pump, but did not work on my M pump, I switched this morning to the metal round vac switch on the right and it works great!

the green thing on the right is a mercedes vac check valve there are lots on the car,

hpe this helps

[/QUOTE]

[/QUOTE]Seems like I read he is not using the Mercedes solenoid, but the Jeep vapor canister solenoid, I think it is a normally closed instead of normally open valve, so it has to be denergized while the engine is running. I have read others have just put a pin hole in the line to allow it to leak down, but I think the three port check valve will work better because your not loosing vacuum from the intentional leak.

#19

so a couple notes after a week of driving.

for some reason my gas gauge doesnt work the same as before, so i ran out of gas. seems you need to re bleed the lines after an event such as this.

and besides that, this thing runs amazing and is a blast to drive. i dont have accurate fuel mileage yet as im waiting for the new gear for the speedo. however im pretty sure i could easily do 90 on 35"s. i installed a 3" magnaflow on this weekend and im so happy with it over no muffler

for some reason my gas gauge doesnt work the same as before, so i ran out of gas. seems you need to re bleed the lines after an event such as this.

and besides that, this thing runs amazing and is a blast to drive. i dont have accurate fuel mileage yet as im waiting for the new gear for the speedo. however im pretty sure i could easily do 90 on 35"s. i installed a 3" magnaflow on this weekend and im so happy with it over no muffler

#20

There seems to be two different sending units used, I'm still running my gas 4 cyl in the Jeep, and when the fuel pump went bad a couple of years back, the replacement had a new sending unit with it. You can fill the tank all the way up, but the guage never goes all the way to full. Mine has the small tank, so I figured the parts house gave me the pump and sending unit for the big tank. I don't drive it far after the light comes on!