Homemade Compression Adapter...

#1

These tools are a necessity for testing compression on the 7.3L Powerstroke diesel. The reasoning for that is there is insufficient clearance between the rocker arm for the angle that the glow plug port goes in for a standard straight adapter to work. It will hit the rocker arm. No fun.

The nice thing about this particular setup is that it can be used on ALL 8 cylinders. You have to mess with the hose a bit on the back cylinders, and you have to noodle past the A/C Compressor for cylinder #1, but it will fit. At least it did on my 99.5 Super Duty.

As a bonus! I've seen a few people on here have TDI's- The 7.3L Powerstroke and the early TDI's (1Z, AHU, and ALH engines) have the same glow plug thread pitch- This tool can ease getting a reading as you don't have to snake the compression tool down amongst the injection lines. Bonus!

Your starting goodies-

An economy diesel compression tester. I know for a fact that the Harbor Freight tool #93644 ( Harbor Freight 12 piece compression tester ) has the 1/8" NPT adapter we will need. So I recommend it.

You'll need a 1/8" NPT female-to-female connector (I call them barrels)

You can get the just about anywhere that has a brass fitting selection. I got mine from Parker Store as it was easier to get it at the same time as our next piece.

You'll need an adapter to fit the actual glow plug port. Parker Store part #M10-1/8F8OHGS accomplishes this. It is our glow plug port thread pitch, M10-1.0, in an O-Ring boss male fitting on one side, but on the other adapts to 1/8"NPT female threads.

You can see if there is a Parker Store near you by searching at McCoy Sales Corporation - McCoy Sales Corporation - Manufacturers Representative and Distributor

If not, here is an internet alternative- ( M10-1/8F8OHGS )

You will need a grease gun hose whip. Not the kind with a fitted grease fitting on one end, but the kind with 1/8"NPT male fittings on both ends. I got mine from Ace, but noone seems to have the 12" whips online.

You can get them pretty much any auto supply store. Autozone should sell a 12" whip for about $4.99. I think I paid $6 at Ace. Either way, it doesn't matter.

You will also either need pipe dope or teflon tape. I won't link that as it should be obvious to anyone who got this far in the writeup.

At this point, lets see....

I paid roughly-

$30 for the compression tester.

$6 for the grease whip.

$1.50 for the barrel adapter

$12 for the M10-1.0 to 1/8" NPT adapter

And I have a healthy supply of teflon tape on hand.

So, thats roughly $50 into this venture, about $20 into the adapter. Beats the price of just the adapter from Snap-On.

So here we go with the visuals!

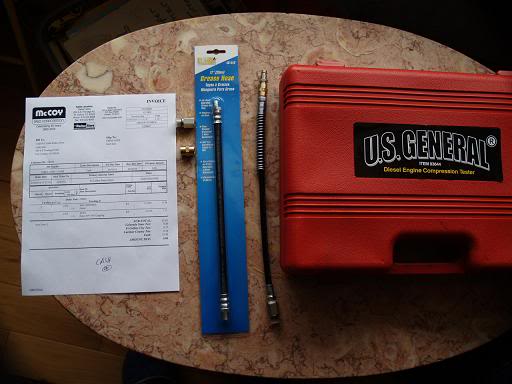

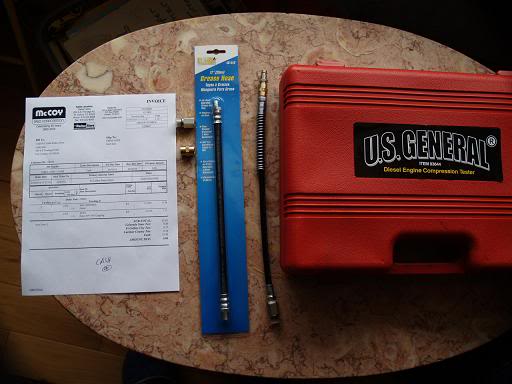

Here's what you need, plus an already assembled whip!

A closer look of whats required to make the whip-

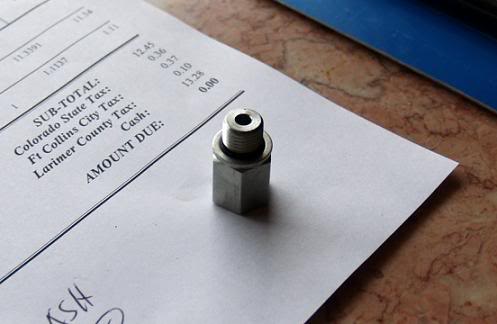

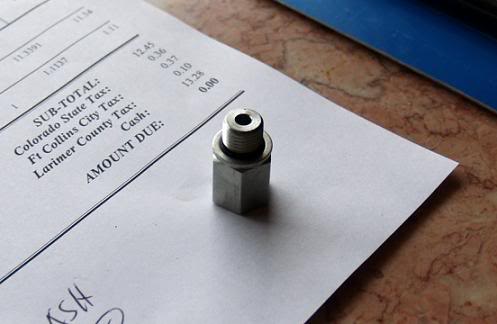

And a close-up of the kicker part of the setup- the M10-1.0 O-Ring Boss to 1/8"NPT female adapter-

So. What you will need to do is either pipe-dope or teflon tape both ends of the grease gun whip. If you use the tape, make sure when you put it on the threads you wind it such that when you go to put on the adapters they will spin in the same direction the tape was wound. If you do it the wrong way, it tends to bunch up and not be too effective.

Once you've teflon taped up the grease whip, attach your 1/8" NPT barrel connector to one end of the whip, and the O-Ring boss adapter onto the other. Make sure you are snug, but don't go crazy. We don't want to damage threads. But also remember, your new compression fitting must withstand upwards off 500PSI. Thus the grease whip as they are usually rated with a working pressure rating of 3000-5000PSI.

Believe it or not, thats as simple as it is! You now have a compression adapter whip ready to accept the 1/8"NPT adapter for your diesel compression testing kit!

A view of the adapter side-

And here is a view of the barrel side, with the 1/8"NPT compression adapter threaded in-

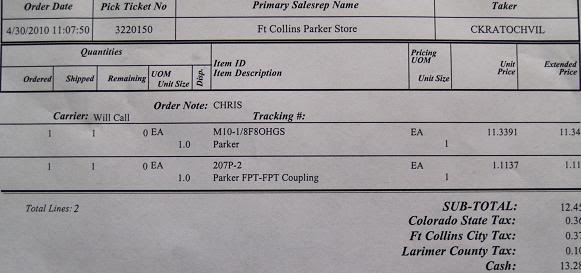

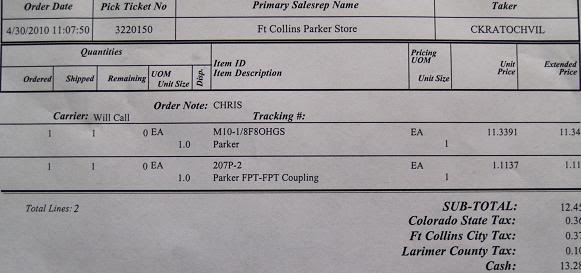

And for those of you who want to be sure I typed out the adapter part number correctly, a view of my invoice-

Now, to let you know. When performing a compression test on a stock 7.3L, there are no "official" ratings. Ford and International go by a blowby rating, measured with specialized tool and orifice adapters that are hard to come by. One must remember to maintain cranking speed throughout the test. Hooking up a battery charger helps a lot.

While there is no "official" rating, its generally accepted that 350 is the lowest end of healthy. Much below that and you might have some wear concerns.

The big thing to look out for in consistency. I don't like to see more than a 15% difference between the lowest cylinder and the highest. Some say 25%.

But bear in mind altitude also has a pretty drastic effect that can be calculated using these numbers (Thanks Tom S!)

1,000 feet = .9711,

2,000 feet = .9428,

3,000 feet = .9151,

4,000 feet = .8881,

5,000 feet = .8617,

6,000 feet = .8359,

7,000 feet = .8106,

8,000 feet = .7860

SO! If we have a reading of 302PSI at 6000 feet, that 302 is only 0.8359 of what it would be at sea level. Calculated out,

Solve for x.

0.8359x=302

Divide both sides by 0.8359.

302/0.8359= (.8359x)/.8359

361.29=x

Hope this helps!

The nice thing about this particular setup is that it can be used on ALL 8 cylinders. You have to mess with the hose a bit on the back cylinders, and you have to noodle past the A/C Compressor for cylinder #1, but it will fit. At least it did on my 99.5 Super Duty.

As a bonus! I've seen a few people on here have TDI's- The 7.3L Powerstroke and the early TDI's (1Z, AHU, and ALH engines) have the same glow plug thread pitch- This tool can ease getting a reading as you don't have to snake the compression tool down amongst the injection lines. Bonus!

Your starting goodies-

An economy diesel compression tester. I know for a fact that the Harbor Freight tool #93644 ( Harbor Freight 12 piece compression tester ) has the 1/8" NPT adapter we will need. So I recommend it.

You'll need a 1/8" NPT female-to-female connector (I call them barrels)

You can get the just about anywhere that has a brass fitting selection. I got mine from Parker Store as it was easier to get it at the same time as our next piece.

You'll need an adapter to fit the actual glow plug port. Parker Store part #M10-1/8F8OHGS accomplishes this. It is our glow plug port thread pitch, M10-1.0, in an O-Ring boss male fitting on one side, but on the other adapts to 1/8"NPT female threads.

You can see if there is a Parker Store near you by searching at McCoy Sales Corporation - McCoy Sales Corporation - Manufacturers Representative and Distributor

If not, here is an internet alternative- ( M10-1/8F8OHGS )

You will need a grease gun hose whip. Not the kind with a fitted grease fitting on one end, but the kind with 1/8"NPT male fittings on both ends. I got mine from Ace, but noone seems to have the 12" whips online.

You can get them pretty much any auto supply store. Autozone should sell a 12" whip for about $4.99. I think I paid $6 at Ace. Either way, it doesn't matter.

You will also either need pipe dope or teflon tape. I won't link that as it should be obvious to anyone who got this far in the writeup.

At this point, lets see....

I paid roughly-

$30 for the compression tester.

$6 for the grease whip.

$1.50 for the barrel adapter

$12 for the M10-1.0 to 1/8" NPT adapter

And I have a healthy supply of teflon tape on hand.

So, thats roughly $50 into this venture, about $20 into the adapter. Beats the price of just the adapter from Snap-On.

So here we go with the visuals!

Here's what you need, plus an already assembled whip!

A closer look of whats required to make the whip-

And a close-up of the kicker part of the setup- the M10-1.0 O-Ring Boss to 1/8"NPT female adapter-

So. What you will need to do is either pipe-dope or teflon tape both ends of the grease gun whip. If you use the tape, make sure when you put it on the threads you wind it such that when you go to put on the adapters they will spin in the same direction the tape was wound. If you do it the wrong way, it tends to bunch up and not be too effective.

Once you've teflon taped up the grease whip, attach your 1/8" NPT barrel connector to one end of the whip, and the O-Ring boss adapter onto the other. Make sure you are snug, but don't go crazy. We don't want to damage threads. But also remember, your new compression fitting must withstand upwards off 500PSI. Thus the grease whip as they are usually rated with a working pressure rating of 3000-5000PSI.

Believe it or not, thats as simple as it is! You now have a compression adapter whip ready to accept the 1/8"NPT adapter for your diesel compression testing kit!

A view of the adapter side-

And here is a view of the barrel side, with the 1/8"NPT compression adapter threaded in-

And for those of you who want to be sure I typed out the adapter part number correctly, a view of my invoice-

Now, to let you know. When performing a compression test on a stock 7.3L, there are no "official" ratings. Ford and International go by a blowby rating, measured with specialized tool and orifice adapters that are hard to come by. One must remember to maintain cranking speed throughout the test. Hooking up a battery charger helps a lot.

While there is no "official" rating, its generally accepted that 350 is the lowest end of healthy. Much below that and you might have some wear concerns.

The big thing to look out for in consistency. I don't like to see more than a 15% difference between the lowest cylinder and the highest. Some say 25%.

But bear in mind altitude also has a pretty drastic effect that can be calculated using these numbers (Thanks Tom S!)

1,000 feet = .9711,

2,000 feet = .9428,

3,000 feet = .9151,

4,000 feet = .8881,

5,000 feet = .8617,

6,000 feet = .8359,

7,000 feet = .8106,

8,000 feet = .7860

SO! If we have a reading of 302PSI at 6000 feet, that 302 is only 0.8359 of what it would be at sea level. Calculated out,

Solve for x.

0.8359x=302

Divide both sides by 0.8359.

302/0.8359= (.8359x)/.8359

361.29=x

Hope this helps!

#2

I used an alternative method to accomplish the same thing. I got the harbor freight tester. Then I took an old glow plug and broke the guts out of it. Next I brazed a piece of 3/16 inch brake line into it and a pipe adapter onto the top to screw the 1/8 pipe disconnect coupling into. The 3/16 brake tubing will fit past the rocker arms and push rods. http://www.4shared.com/photo/9M5-izmj/100_0075.html

#3

#4

#5

Not to sound dense, but I don't get it. I have the parker hydraulic fitting and the collar, but I can't figure out how to connect the HF gauge set up to the home made adapter.

The last picture shows the compression adapter threaded into the brass barrel. OK. So that goes into the quick release compression fitting on the end of the gauge elbow. Now what?

The make 1/8 NPT on the hydraulic fitting screws into what?

The HF fitting that goes into the glow plug hole is also compression fitting. I would need a 1/8 female to female compression quick release to get it to work.

One thing I tried was to remove the compression quick release from the end of the HF hose, screw in the parker hydraulic fitting into that, then put the HF male 1/8 female quick release to the end of the brass barrel. That allowed it all to go together.

However, when the HF glow plug fitting is screwed into the head, I cannot get the quick release to connect to it.

Any insight would be much appreciated. Thanks.

The last picture shows the compression adapter threaded into the brass barrel. OK. So that goes into the quick release compression fitting on the end of the gauge elbow. Now what?

The make 1/8 NPT on the hydraulic fitting screws into what?

The HF fitting that goes into the glow plug hole is also compression fitting. I would need a 1/8 female to female compression quick release to get it to work.

One thing I tried was to remove the compression quick release from the end of the HF hose, screw in the parker hydraulic fitting into that, then put the HF male 1/8 female quick release to the end of the brass barrel. That allowed it all to go together.

However, when the HF glow plug fitting is screwed into the head, I cannot get the quick release to connect to it.

Any insight would be much appreciated. Thanks.

#6

The quick release fitting and 1/8 pipe coupling goes on one end of the grease hose and the 10mm male to 1/8 female pipe adapter that fits the glow plug threads in the head goes on the other end of the grease hose.after it is put together you just twist the hose to screw the adapter into the head and snap the compression tester to the quick disconnect.

Thread

Thread Starter

Forum

Replies

Last Post

01stroker7.3

Ford Powerstroke 99-03 7.3L

3

07-17-2015 01:47 AM

RLLBZ

Chevy/GMC Duramax 01-04 LB7

1

01-27-2015 03:05 PM