Installing a 5.9 Cummins New Rear Main Seal*

#1

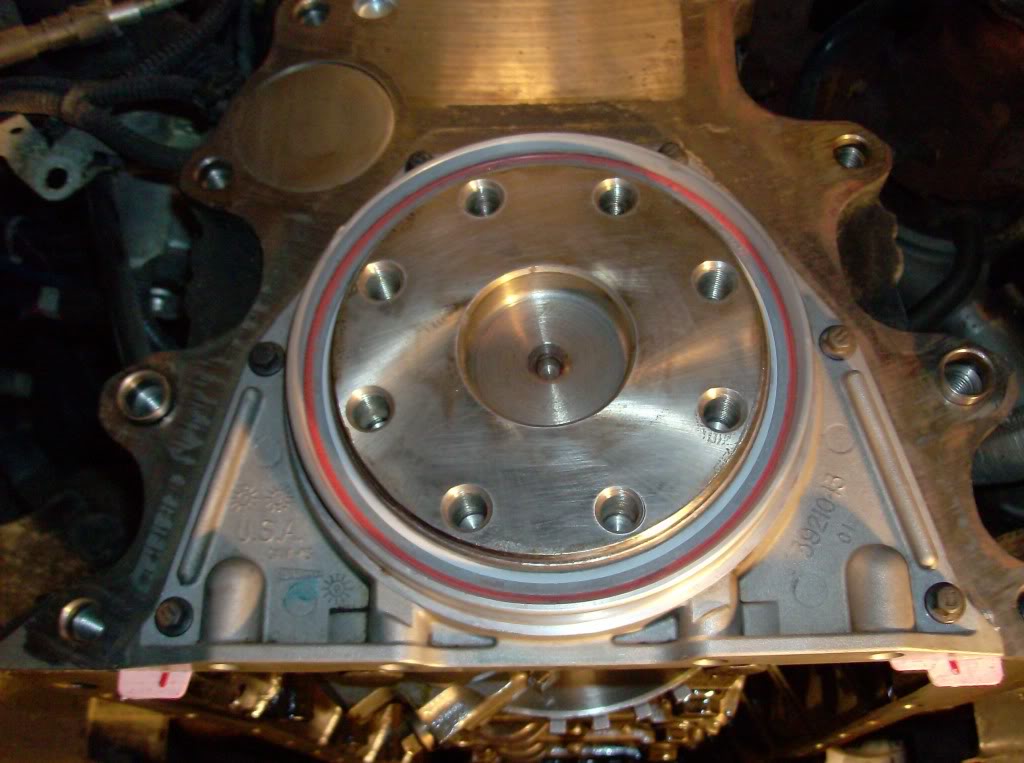

Here is a basic breakdown of the rear main seal on a 1999 24Valve 5.9 Cummins.

Once the transmission and torque converter or clutch is removed.

Remove the flywheel or flexplate.

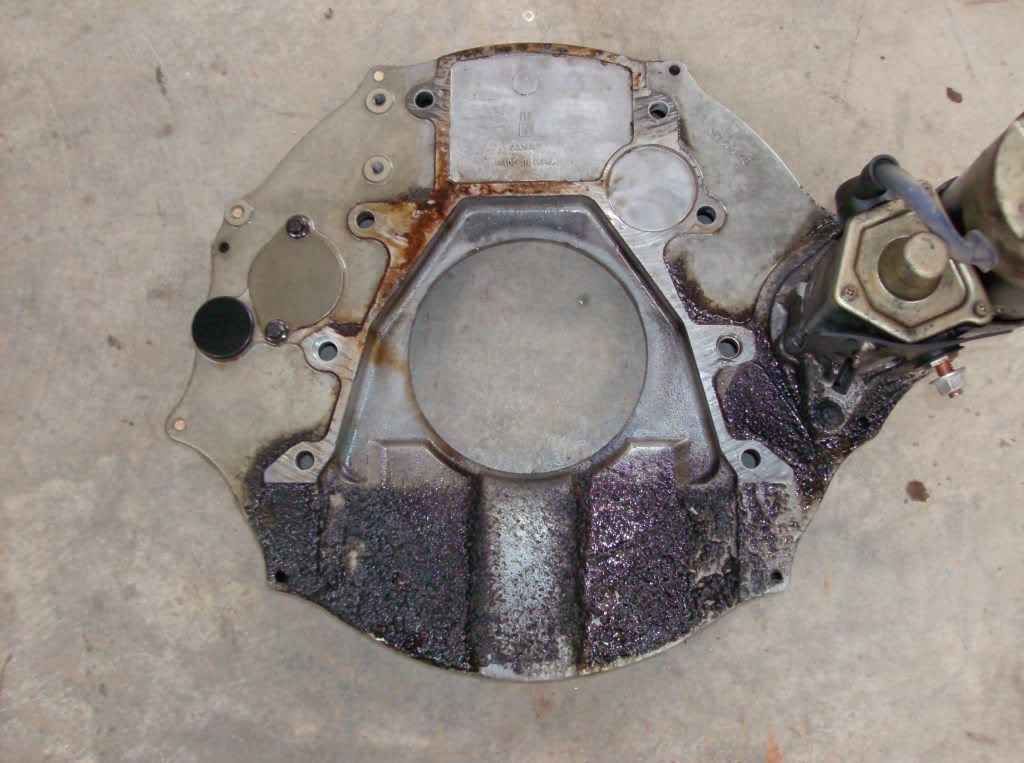

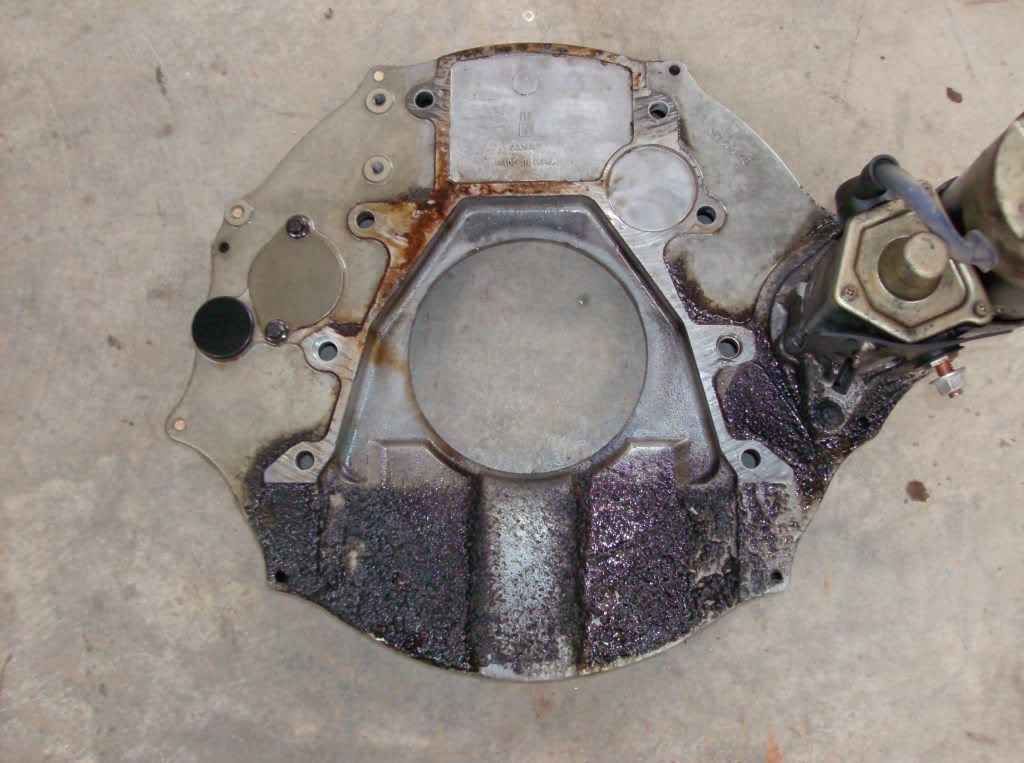

There is a bell housing adapter plate that holds the starter and adapts the engine to the transmission.

Remove the six bolts and the two starter wires and this comes off.

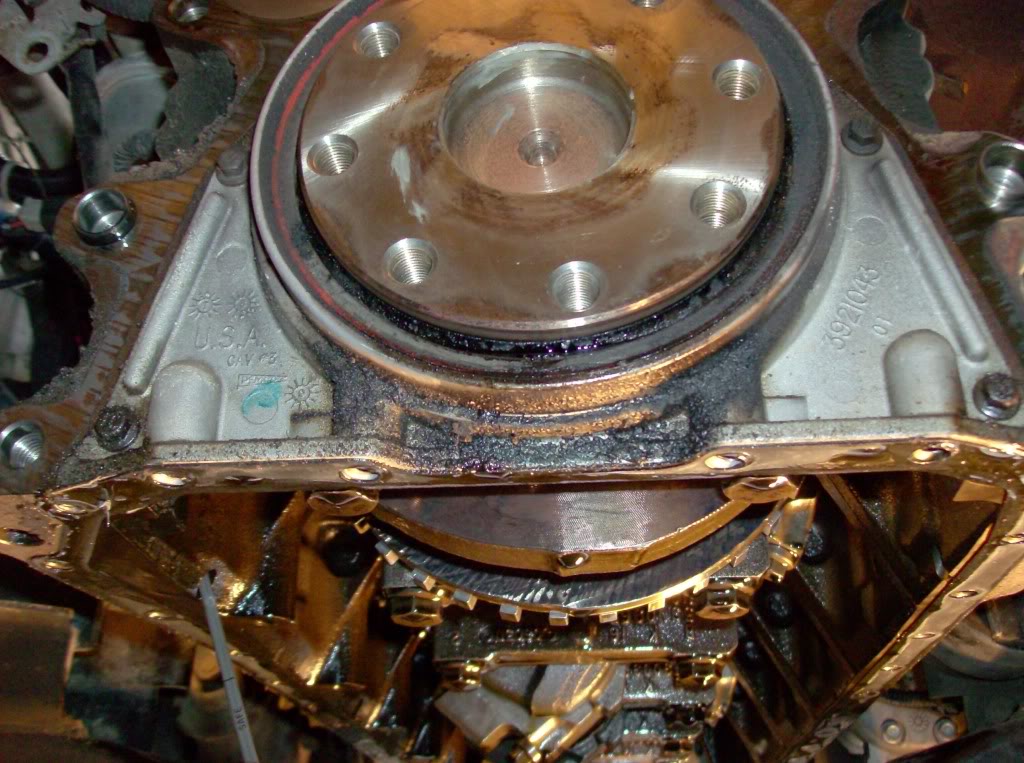

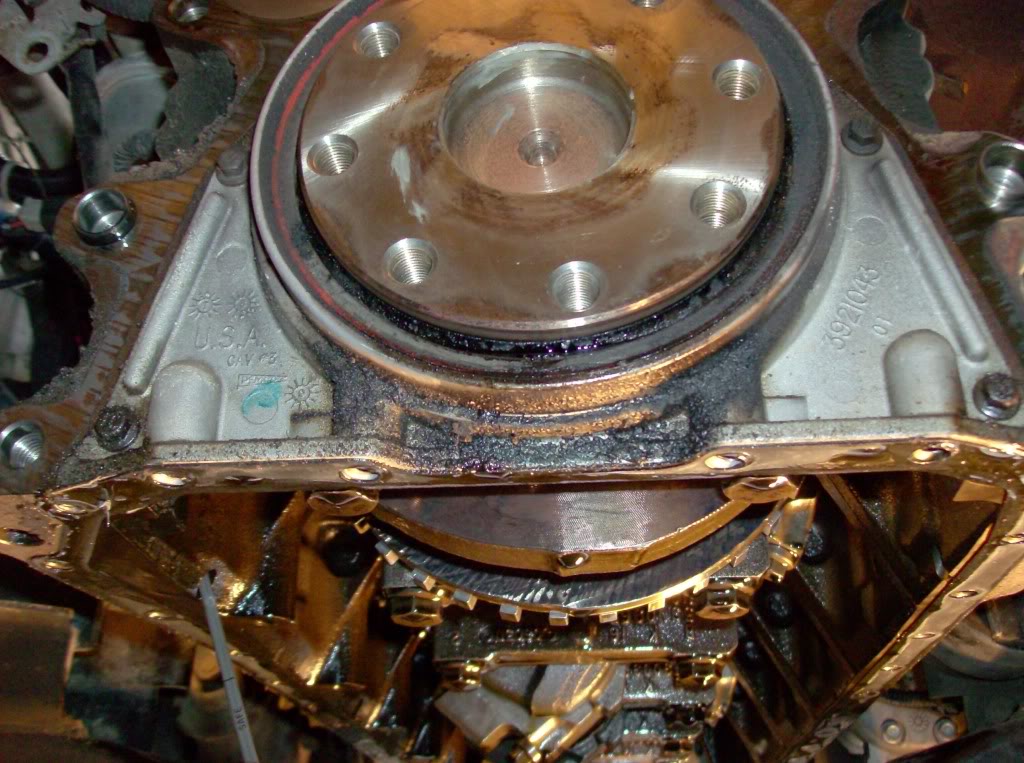

The seal housing has six bolts to the block and five through the oil pan.

Once the seal housing is removed carefully remove the seal with a suitable driver or press.

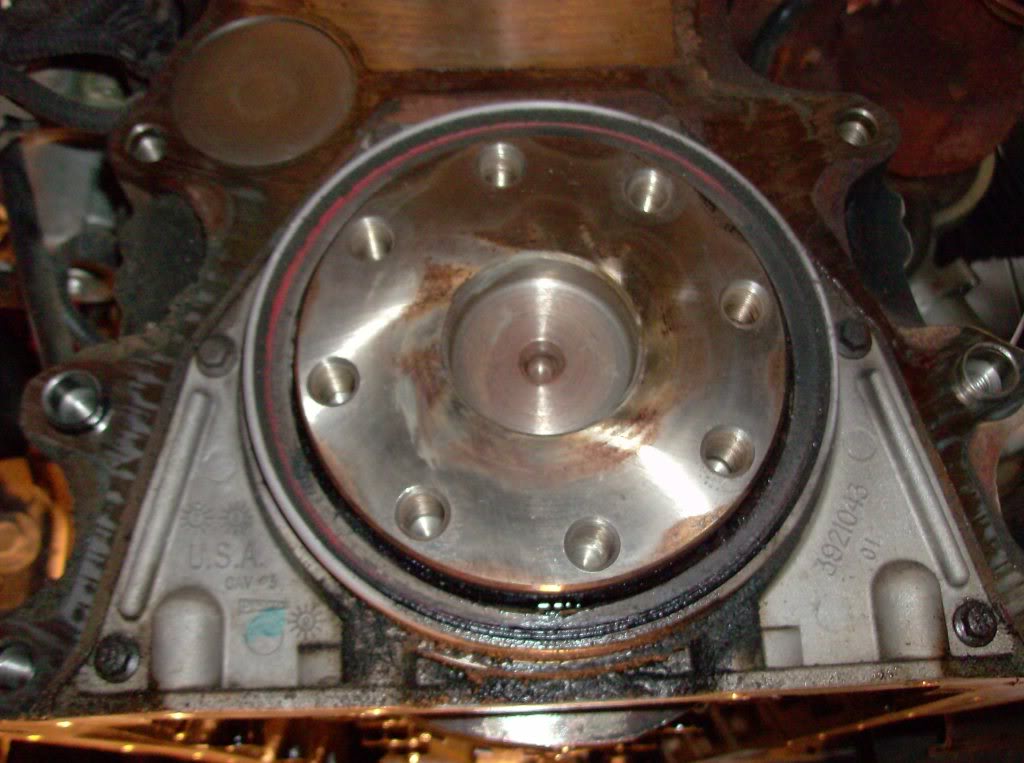

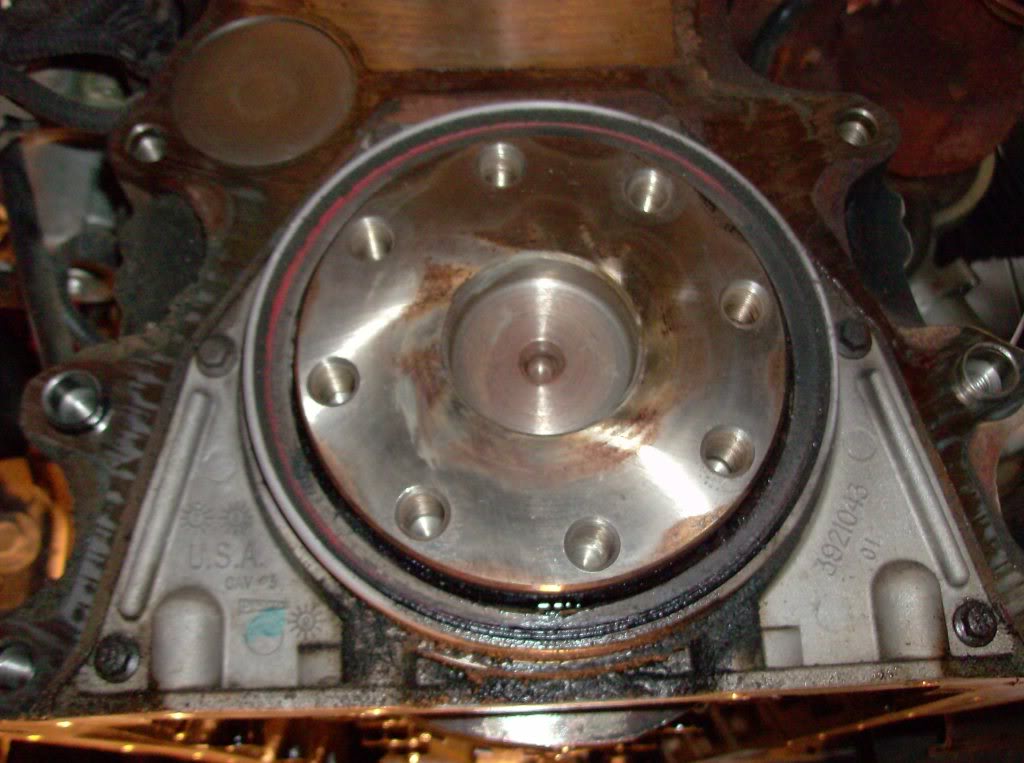

In the pictures you can see the wear on the crank journal, you can get just the seal or a seal and sleeve.The seal and sleeve aren't cheap about 85$ from Cummins.

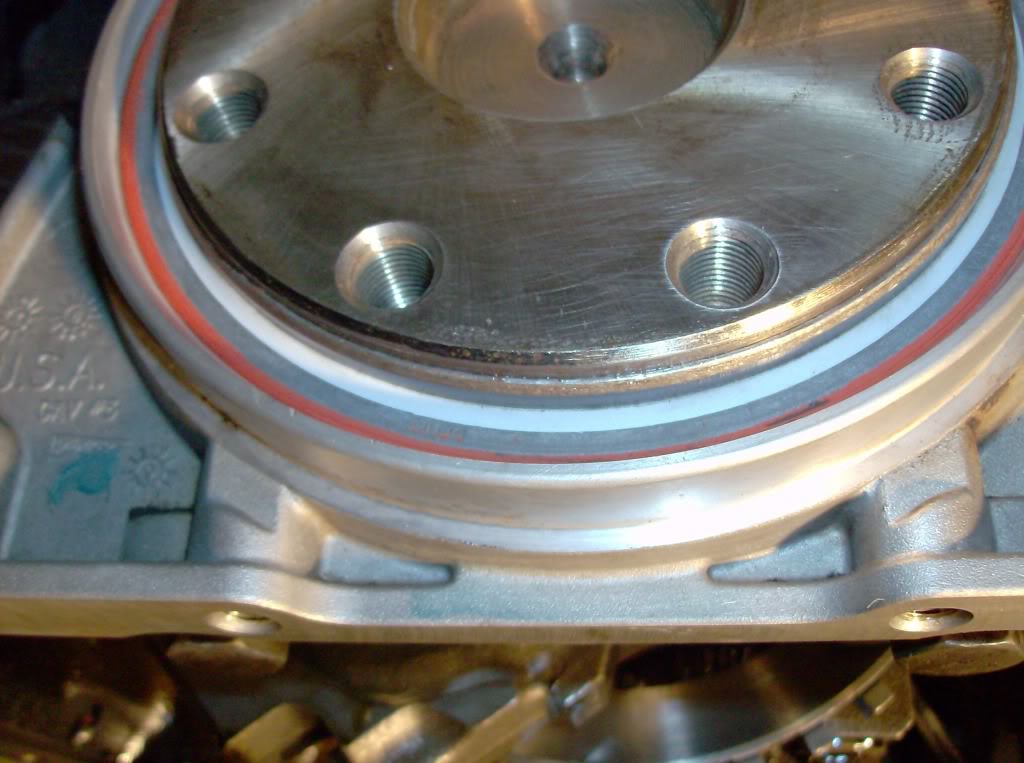

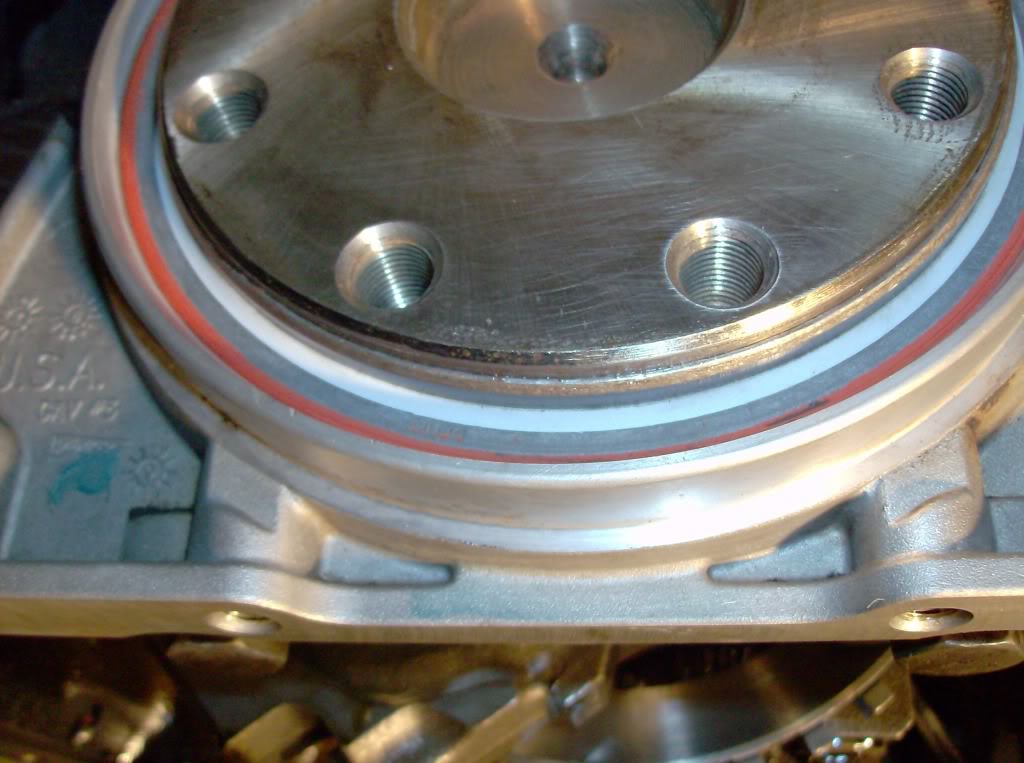

The instructions are supplied with the seal and sleeve that state, "do not remove the sleeve from the seal" if you do it will be very difficult to install the seal housing back on the engine without damaging the seal. I installed the sleeve first on the crank then using a transmission clutch pack loop tool worked the seal around the crank very carefully it can be done but very difficult. It is better to keep it together as one piece.

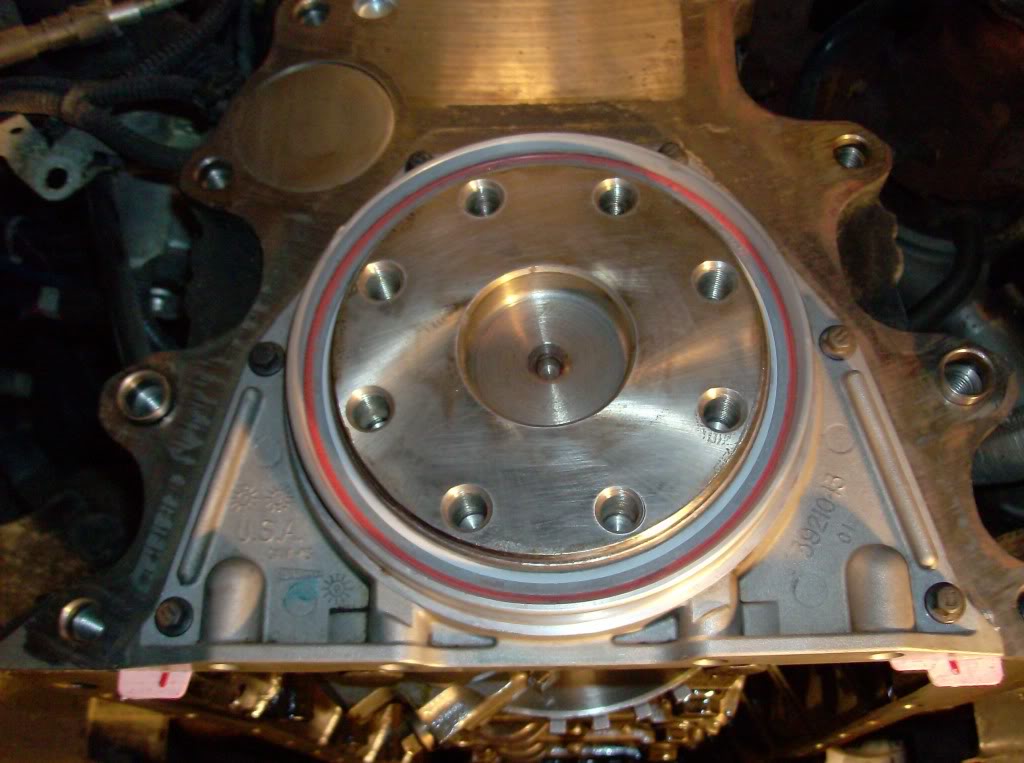

Install the seal into the seal housing using some liquid dish soap around the outside to help it slide in. Using a press or suitable large diameter driver (the old seal), press the seal in the housing to a depth just inside the taper of the seal housing.make sure it even all the way around.

The instructions included with the new seal and sleeve doesn't say to use any loctite on the new sleeve that goes over the crankshaft hub. But i used some cylindrical loctite (for Pres fit bearings).

There is a tool required that pushes the sleeve,seal and housing assembly over the end of the crank, it basically has the same bolt pattern as the crank flange and slightly larger than the diameter of the sleeve. The tool helps keep the sleeve square as its drawn down with the flywheel bolts 1/2 turn at a time.

The tool also determines the distance that the sleeve is over the end of the crankshaft this is important because if its slid to far back the seal may ride in the wrong place on the new sleeve.

If its not back far enough it will interfere with the flange on the flywheel and not allow it to sit flush on the crankshaft ( because of a shelf cut into the flywheel).

You can build the tool using an 1/4" or thicker aluminum plate, transfer the flywheel/flexplate bolt spacing to the plate and drill to the size of the bolts 1/2" bit works good. This home made tool will allow you to push the sleeve on evenly.

Once the sleeve is flush with the end of the crank use the flywheel to push it back the distance of the "setback" caused by the shelf in the flywheel.

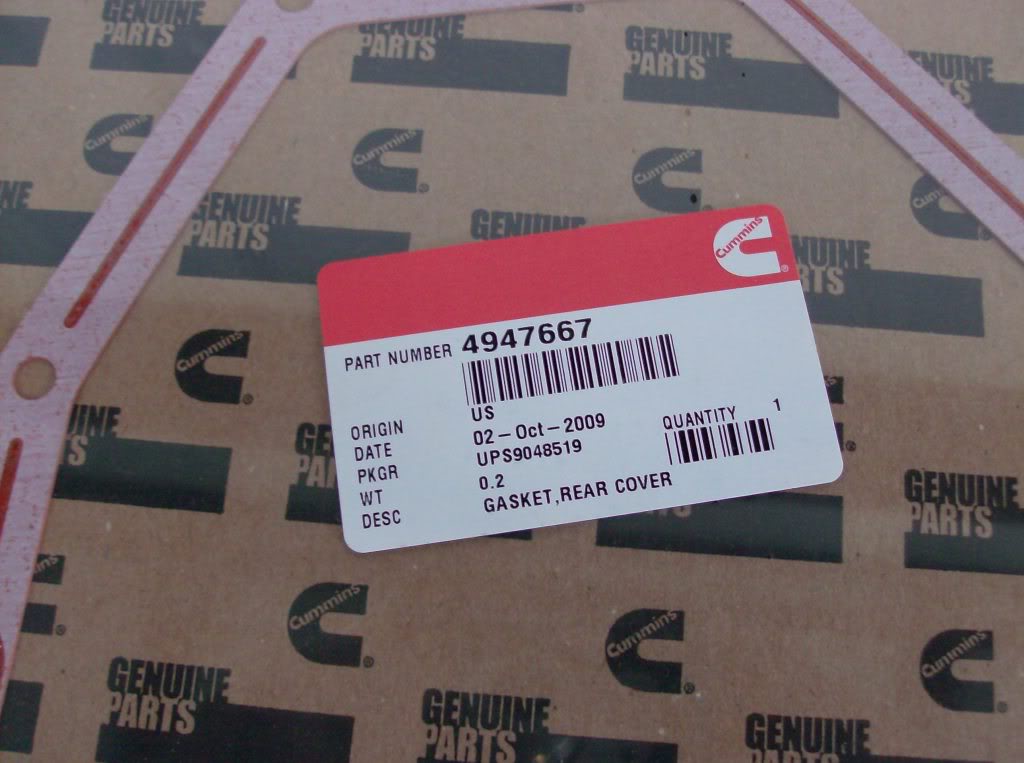

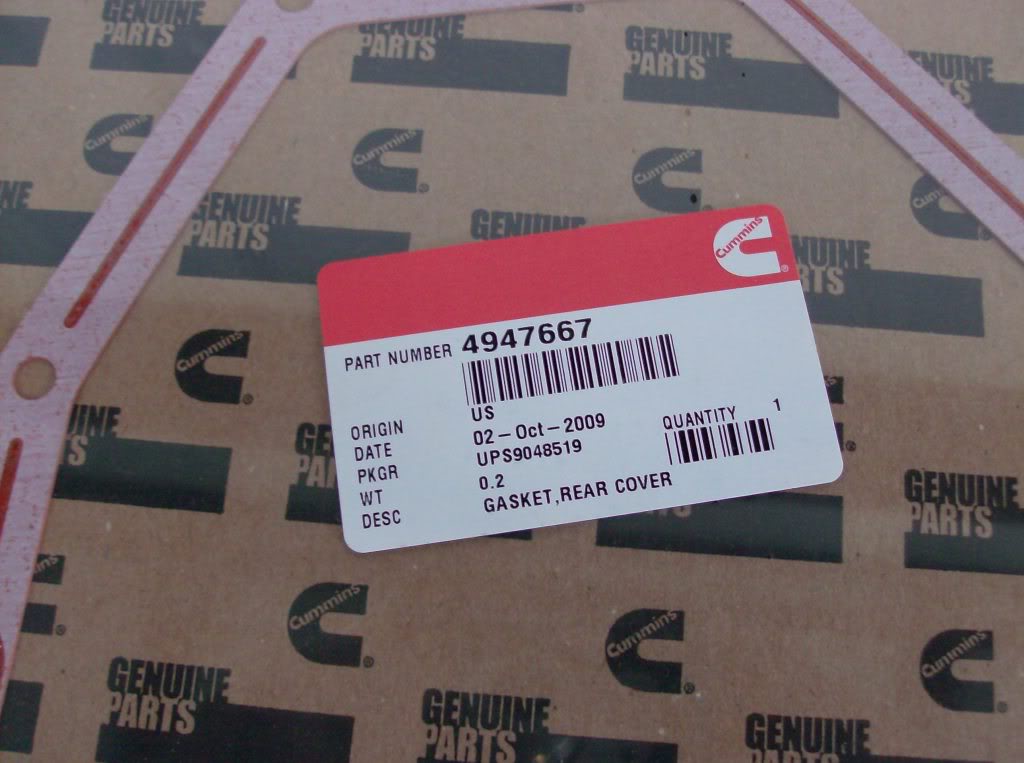

When installing the gasket on the seal housing you will need to trim the extra length that hangs over at the end of the housing so that it is even with the edge.This is a lot easier if the oil pan was removed and after the seal housing is installed then it can be cut even with the engine to oil pan surface.

You will need the following parts:

Rear seal housing gasket Cummins Part # 4947667

Rear Seal with Sleeve Cummins Part #3926126

I hope this helps someone out.

Once the transmission and torque converter or clutch is removed.

Remove the flywheel or flexplate.

There is a bell housing adapter plate that holds the starter and adapts the engine to the transmission.

Remove the six bolts and the two starter wires and this comes off.

The seal housing has six bolts to the block and five through the oil pan.

Once the seal housing is removed carefully remove the seal with a suitable driver or press.

In the pictures you can see the wear on the crank journal, you can get just the seal or a seal and sleeve.The seal and sleeve aren't cheap about 85$ from Cummins.

The instructions are supplied with the seal and sleeve that state, "do not remove the sleeve from the seal" if you do it will be very difficult to install the seal housing back on the engine without damaging the seal. I installed the sleeve first on the crank then using a transmission clutch pack loop tool worked the seal around the crank very carefully it can be done but very difficult. It is better to keep it together as one piece.

Install the seal into the seal housing using some liquid dish soap around the outside to help it slide in. Using a press or suitable large diameter driver (the old seal), press the seal in the housing to a depth just inside the taper of the seal housing.make sure it even all the way around.

The instructions included with the new seal and sleeve doesn't say to use any loctite on the new sleeve that goes over the crankshaft hub. But i used some cylindrical loctite (for Pres fit bearings).

There is a tool required that pushes the sleeve,seal and housing assembly over the end of the crank, it basically has the same bolt pattern as the crank flange and slightly larger than the diameter of the sleeve. The tool helps keep the sleeve square as its drawn down with the flywheel bolts 1/2 turn at a time.

The tool also determines the distance that the sleeve is over the end of the crankshaft this is important because if its slid to far back the seal may ride in the wrong place on the new sleeve.

If its not back far enough it will interfere with the flange on the flywheel and not allow it to sit flush on the crankshaft ( because of a shelf cut into the flywheel).

You can build the tool using an 1/4" or thicker aluminum plate, transfer the flywheel/flexplate bolt spacing to the plate and drill to the size of the bolts 1/2" bit works good. This home made tool will allow you to push the sleeve on evenly.

Once the sleeve is flush with the end of the crank use the flywheel to push it back the distance of the "setback" caused by the shelf in the flywheel.

When installing the gasket on the seal housing you will need to trim the extra length that hangs over at the end of the housing so that it is even with the edge.This is a lot easier if the oil pan was removed and after the seal housing is installed then it can be cut even with the engine to oil pan surface.

You will need the following parts:

Rear seal housing gasket Cummins Part # 4947667

Rear Seal with Sleeve Cummins Part #3926126

I hope this helps someone out.

Last edited by Jet A Fuel; 01-06-2010 at 03:58 PM.

The following 4 users liked this post by Jet A Fuel:

Thread

Thread Starter

Forum

Replies

Last Post

yfzrunner

12 Valve 2nd Gen Dodge Cummins 94-98

1

09-17-2015 05:23 AM

plumberjack

Diesel In Distress - Support Ticket

29

03-03-2015 11:38 PM