head work

#1

#3

Carrhartt pockets are pretty deep Haha there not full though. I've been reading around and some people say 300-500 bucks. Its gunna be daily driver/ sledpuller/ and pull car trailor with around 12000 total extra on trips. I heard a good job really helps egts. Can't torture out where to get it done,

#5

#6

#7

#8

I have a p7100 that will be going on down the road, I needs rebuild, nuthin not doinbit for power im doing it for lower egts when the motor is done it will be running atleast 500hp after p pump and while head is off it only makes sense to have thenport polish done now. Does anyone know anywhere good in Washington that does it on diesel heads thanks, you don't need 24v head for p pump you just have to change front gear housing

Last edited by codycatract; 09-15-2012 at 09:39 PM.

#9

do them your self mac tools sells a long shank acorn burr for a die grinder knock all the casting marks off gasket match I & E smooth out the ramp along the valve guide then get get the sanding kit from harbor freight tools for the die grinder smooth it all work from 80 grit up to 320 grit then get a buffer kit also from HFT for a die grinder and polish it out. the very first head i ever did thats what i bought it took me 15 hours i polished every square inch of the inside of that head put it all together and it was noticeable in the gauges not in the feel factor. it was a fun road to go down. since i have done 4 more heads it cost alot and i do them the same way. unless you have money to blow or your going for a world record i dont recommend doing it its just not worth the time and money for the gain unless you do it yourself even then its hard to justify but if you want to pay someone its $1800 for me to do it

#10

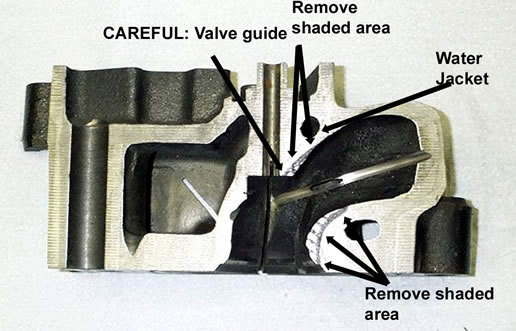

The porting of the 12v CTD head can be very costly with an ample engine build budget. A properly ported head goes way beyond simply hogging-out everything. A true head-porting professional will have and use a flow-bench to measure actual improvements in flow, at varying valve lifts, with each round of whittling. It's not just making each port flow a lot, it's also making them all flow the same consistent figure.

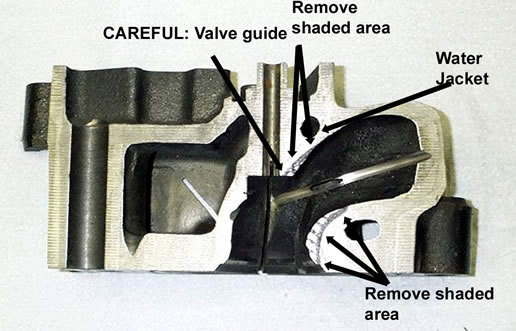

Right off, the 12v head has the intake log (manifold) cast integral with the head. That means that while you can port / clean up the intake bowls, you can't do anything with the intake runners for the intake log being in the way.

Now days, it's common practice to cut the integral intake log off. Machine the remaining head surface, drill and tap bolt holes, and install an aftermarket intake log. The design of the aftermarket intake logs are all over the place. Some being better than others for a given application.

- The point of cutting the integral log off is to have full access to the head's intake runners for porting. You don't necessarily need some fancy voodoo log to bolt back on either.

The stock/OEM cast integral intake log has a rather nasty bolt hole boss cast into things such that the boss is well in the way of intake flow to cylinder #1 . . .

The exhaust side of things is easily accessed for porting.

A few years ago, I got the funds together to buy a mildly ported head and was lucky enough to call PDR at the right time. They had a head that fortunately had all the casting molds in the right places resulting in port walls thick enough to allow a lot of very effective whittling. The customer who the head was built for backed out of the deal and as it happened, that head was the only one they had on the shelf. They let me have it for a good deal.

At the time, PDR advertised the typical stock/OEM 12v head flowed 145CFM (intake), and 153CFM (exhaust). Of course, this is at a given valve opening (lift). The head I got from them flows 195CFM (intake), and 220CFM (exhaust). It included O-rings.

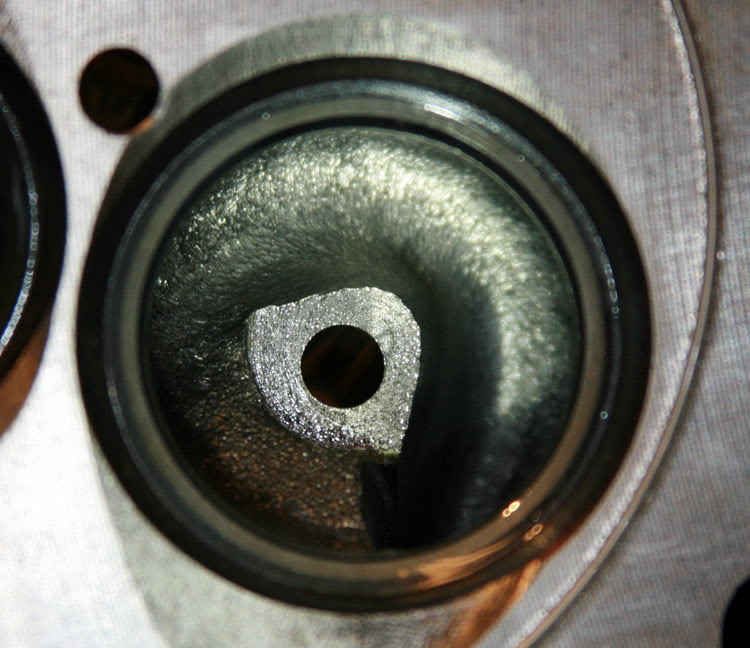

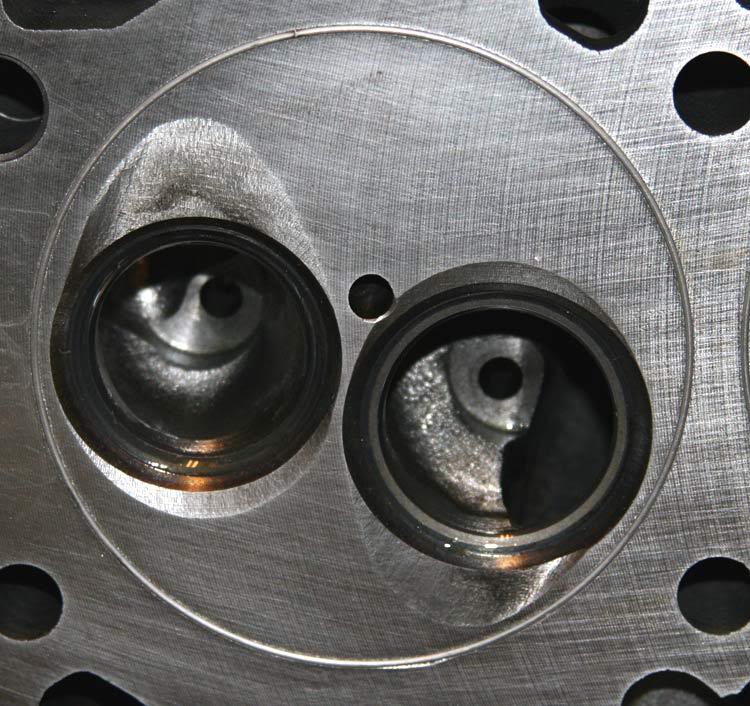

Intake valve bowl . . .

Exhaust valve bowl . . . .

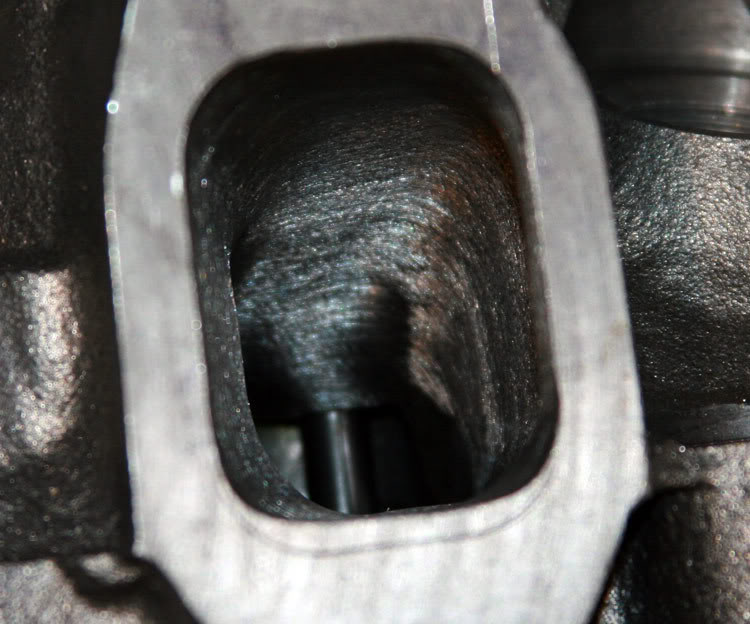

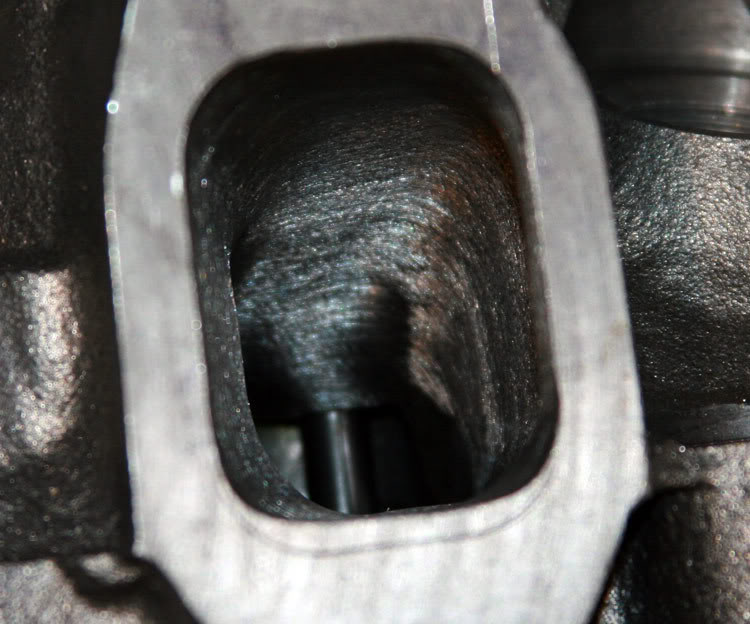

Exhaust port (ceiling) . . .

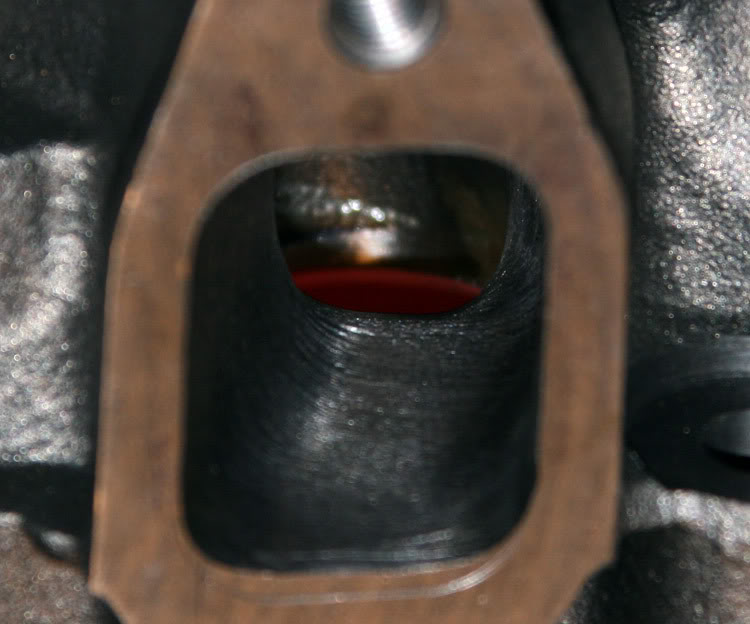

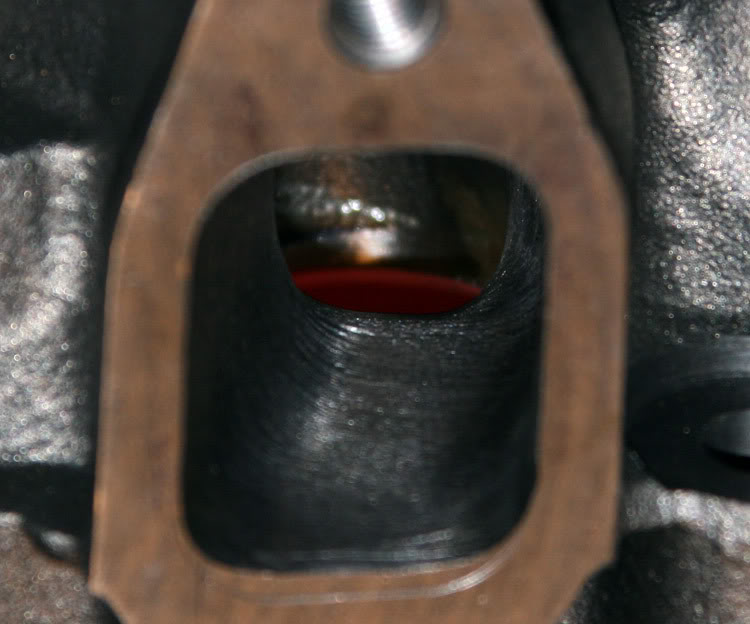

Exhaust port (floor) . . .

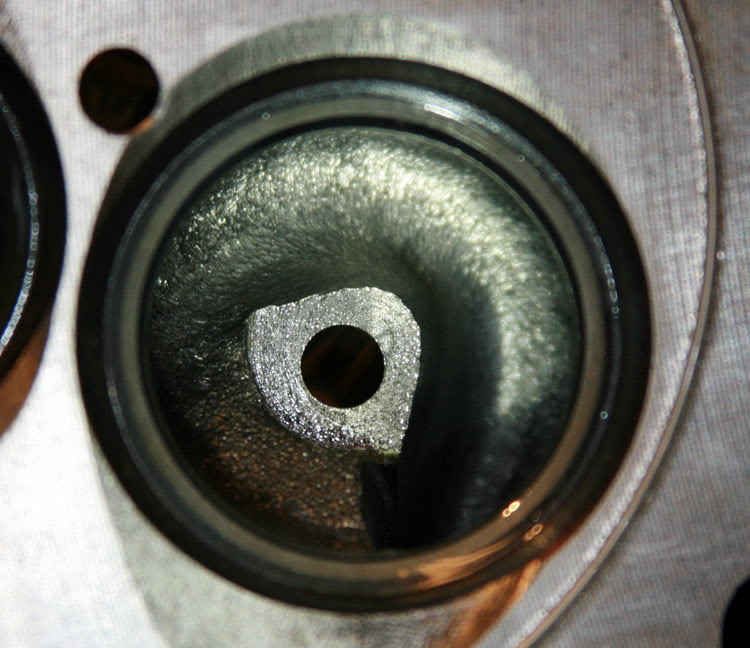

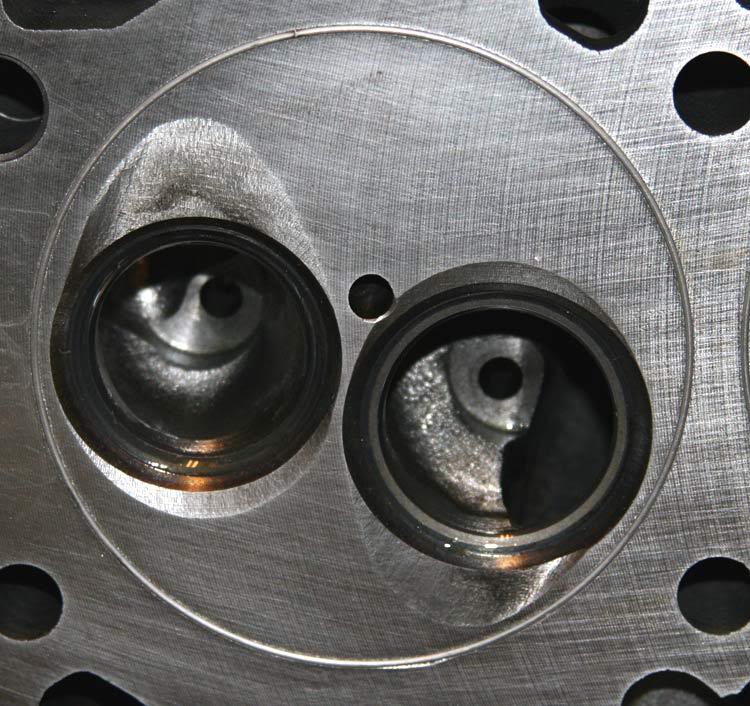

Valve unshrouding . . . .

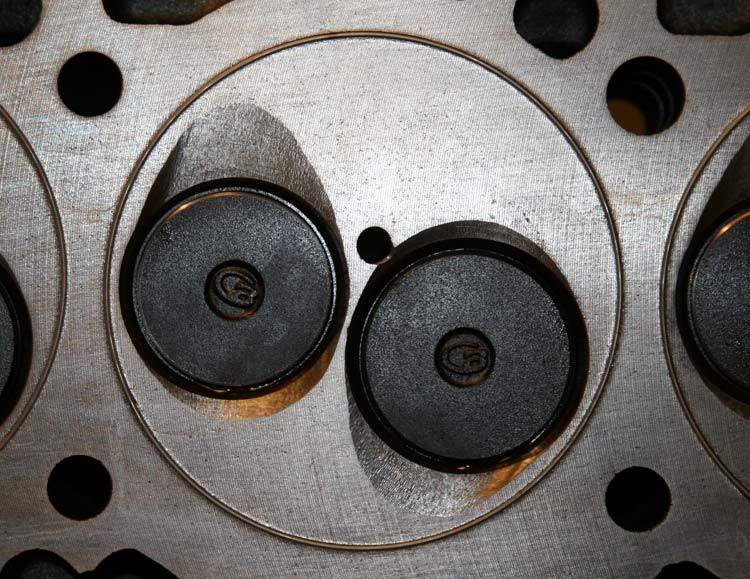

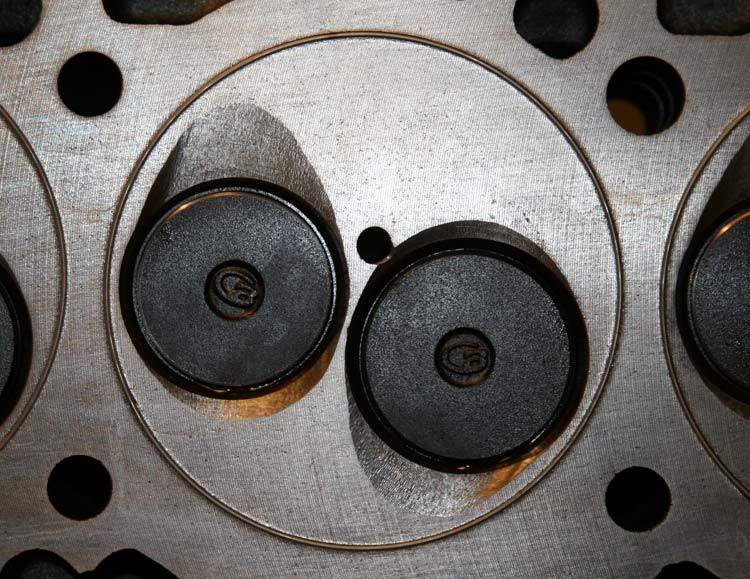

Back-cut valves . . .

The above head combined with a Hamilton 188/220 cam, a Hellman intercooler, conservative twins, etc, flows a lot of air (volume) with a lot less restriction to flow (which means a lower "boost" number changing nothing else).

I like it a lot!

I got it from these folks in Washington: http://www.pdrdiesel.com/cart/catalo...eads-31-1.html

Hope this helps.

Right off, the 12v head has the intake log (manifold) cast integral with the head. That means that while you can port / clean up the intake bowls, you can't do anything with the intake runners for the intake log being in the way.

Now days, it's common practice to cut the integral intake log off. Machine the remaining head surface, drill and tap bolt holes, and install an aftermarket intake log. The design of the aftermarket intake logs are all over the place. Some being better than others for a given application.

- The point of cutting the integral log off is to have full access to the head's intake runners for porting. You don't necessarily need some fancy voodoo log to bolt back on either.

The stock/OEM cast integral intake log has a rather nasty bolt hole boss cast into things such that the boss is well in the way of intake flow to cylinder #1 . . .

The exhaust side of things is easily accessed for porting.

A few years ago, I got the funds together to buy a mildly ported head and was lucky enough to call PDR at the right time. They had a head that fortunately had all the casting molds in the right places resulting in port walls thick enough to allow a lot of very effective whittling. The customer who the head was built for backed out of the deal and as it happened, that head was the only one they had on the shelf. They let me have it for a good deal.

At the time, PDR advertised the typical stock/OEM 12v head flowed 145CFM (intake), and 153CFM (exhaust). Of course, this is at a given valve opening (lift). The head I got from them flows 195CFM (intake), and 220CFM (exhaust). It included O-rings.

Intake valve bowl . . .

Exhaust valve bowl . . . .

Exhaust port (ceiling) . . .

Exhaust port (floor) . . .

Valve unshrouding . . . .

Back-cut valves . . .

The above head combined with a Hamilton 188/220 cam, a Hellman intercooler, conservative twins, etc, flows a lot of air (volume) with a lot less restriction to flow (which means a lower "boost" number changing nothing else).

I like it a lot!

I got it from these folks in Washington: http://www.pdrdiesel.com/cart/catalo...eads-31-1.html

Hope this helps.

Last edited by BC847; 09-15-2012 at 11:03 PM.

The following 2 users liked this post by BC847:

12 valve and proud (09-16-2012),

big bad diesel 416 (09-16-2012)